- Your are here:

- Home >

- High Power Laser cutting machine

Models : BCM6020PE

Application :Metal cutting

Leadtime : 15DAYS

Certificate : CE

Voltage :360V

Customized :YES

Warranty : 3YEARS

Supply Ability : 30SET/MONTH

Oversea Warehouse&Office : DUBAI

- Advantage

- Details

- Specifications

- Videos

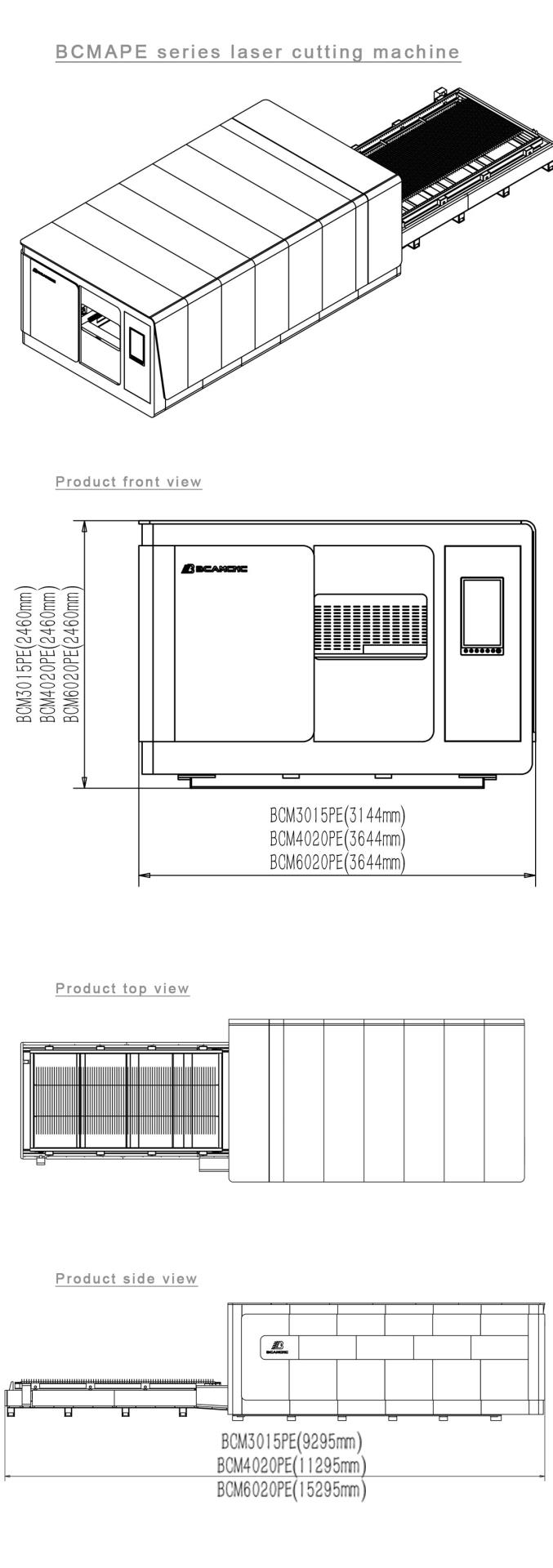

- Foot print

- Download

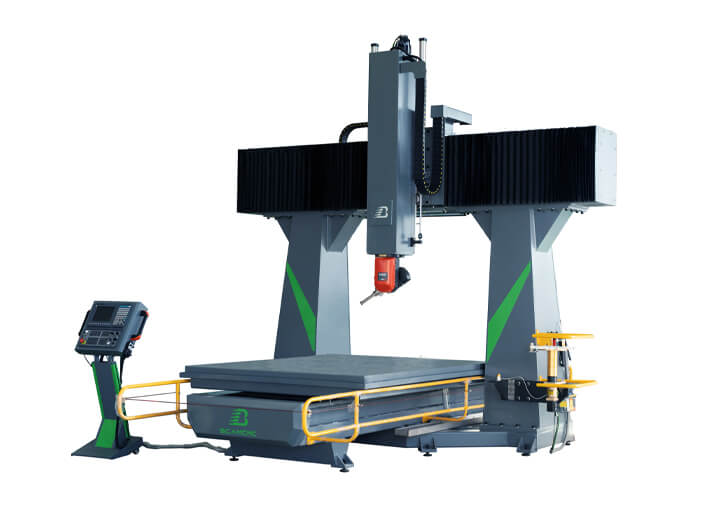

1. HiPower Series Pure technology, developed by BCAM

With dynamic Taiwan linear motors on three axis, a modern composite body and the Raytools cutting head, also provides high performance. The Laser cutters in the BCAM HiPower series achieve positioning speeds of up to 150 m/min, 3G acceleration and fber laser source power of up to 20 kW..

2. The ideal machine concept

The HiPower series of laser cutting machines is characterized by high dynamics and top quality. The machines achieve acceleration of 3G and a positioning speed of up to 150m/min. They are characterized by the highest cut part precision and failure-free operation. Each laser cutter is available with a fber laser source with power ranging from 1 to 20 kW. Laser metal cutting machines take up the least amount of room of the machines available on the market, and easy-to-use software makes it possible to start work immediately.

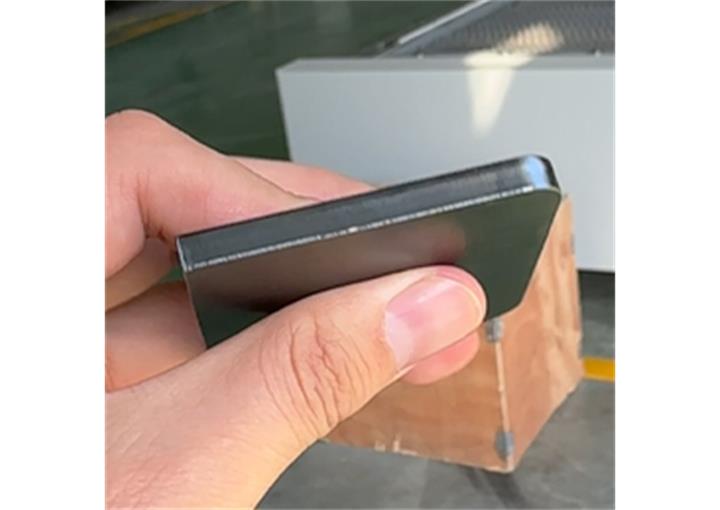

| Laser Cutting Head The cutting head is the most important component in a laser system, and determines both the performance and reliability of the machine. ●The best reliability on the market ●Proven laser power of up to 20kW ●The optic are 2 times less sensitive to contamination ●Cover slide needs replacing 5 times less frequently ●Only 4 consumable parts |

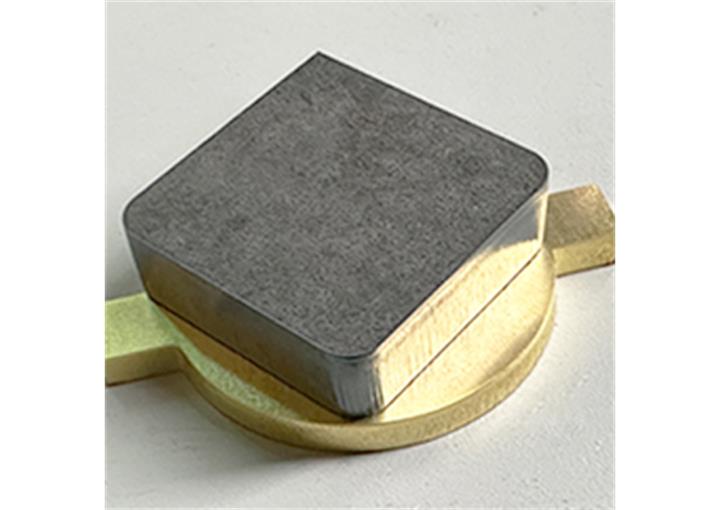

Rigid and stable The machine body is made by High-performance steel with Integrated welding technology , This type of material has unique mechanical properties ●it has a vibration damping factor that is one hundred times higher than that of steel ●Perfect strength, accuracy and durability ●The temperature coefficient is ten times lower ●High thermal capacity ●The best basis for linear motors |  |

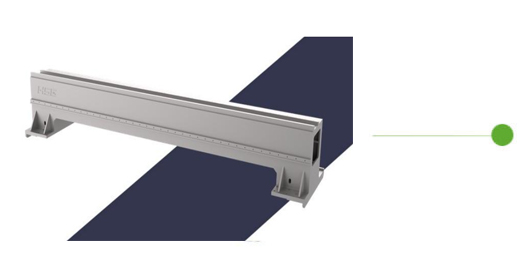

| Aircraft Aluminium traverse bridge The steel traverse bridge is manufactured with extreme precision to ensure that high cutting accuracy is maintained with high acceleration. Its special design eliminates Abbe Errors (linear displacement caused by a rotational error) and wobble, in order to maintain appropriate rigidity during fast cutting. Precision linear guides are positioned around the center of gravity on the base axes to provide high acceleration and accuracy. |

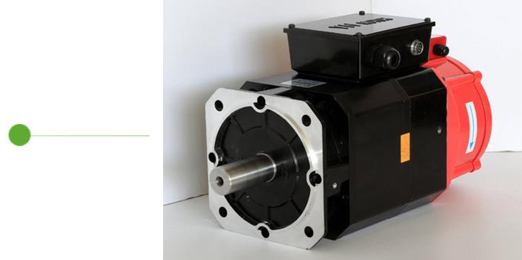

Speed, acceleration and precision Every BCAM fiber laser is equipped with Japan linear Servo motors on all movement axes. Linear motors provide high acceleration/deceleration and high dynamic accuracy. Unlike mechanical drives, linear motors do not lose energy converting rotational motor motion to linear traverse motion. |  |

| Built for speed The fiber laser is provided by IPG Photonics, the undisputed world leader in the production of sheet metal cutting fiber lasers. IPG's innovative products are characterized by their very high energy efficiency of more than 50%, higher productivity, reduced operating costs, ease of operation and integration, and compact design. The main features of these laser sources are energy efficiency and reliability. Fiber lasers have a dynamic power range that allows the beam to focus and maintain a constant position, even after the laser power has been changed. |

Industrial Fiber Laser Cutting Machine (1000W-20000W)

| ● Working area: 1500*3000mm |

|---|

| ● Cypcut control system |

| ● Taiwan PMI ball screw |

| ● Taiwan ABBA gears and racks |

| ● Fiber laser generator 1000W-20000W Raycus(Optional:Germany IPG Laser 1000W-20000W) |

| ● Serrate working platform table |

| ● Wifi remote assistance |

| ● Japan Yaskawa servo motor and drivers |

| ● Location system:Red dot indicator |

| ● Au3Tech laser cutting head+Auto focus function |

| ● Taiwan Hiwin square guide rail |

| ● Japan NSK Beraring |

| ● Industrial CW6200 water chiller |

| ● Heavy duty body frame thickness,more than 9500kg |

Maximum cutting thicknesses

LASER SOURCE | JM | 1kW | 2kW | 3kW | 4kW | 6kW | 8KW | 10kW | 12kW | 15kW | 20kW |

mild steel | [mm] | 10 | 16 | 20 | 20 | 30* | 40* | 50* | 60* | 60* | 60* |

stainless steel | [mm] | 4 | 10 | 15 | 20 | 30* | 40* | 50* | 60* | 60* | 60* |

aluminium | [mm] | 2 | 6 | 12 | 15 | 30* | 35* | 40* | 50* | 50* | 50* |

brass | [mm] | 2 | 4 | 6 | 8 | 12 | 15 | 20 | 30* | 30* | 30* |

copper | [mm] | 1,5 | 4 | 6 | 6 | 10 | 15 | 20 | 25 | 25 | 25* |

Maximum thicknesses of the materials to be processed. The values that are achieved depend on the quality of the material being processed, the quality of the cutting gases, the quality of the service and the NC program and the condition of the wearing parts

* Heavy duty (HD) laser cutter version with CatLine option

Find out More Products

EN

EN Ru

Ru

Tel:0086-15154109683

Tel:0086-15154109683

Fax:0086-15154109683

Fax:0086-15154109683

Mobile:+86 15154109683

Mobile:+86 15154109683

Skype:

Skype: