- Your are here:

- Home >

- Wood lathe

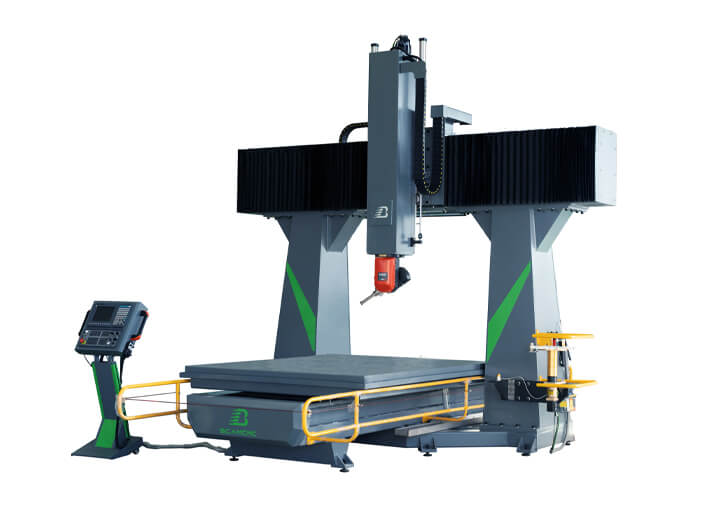

Models : BCM15030

Application :Panel Funiture,Wood&Wood based materials,Plastic&Non ferrous Metarials

Leadtime : 15-20days

Certificate : CE,ISO

Voltage :380V/3P/50HZ,220V/1P/50HZ

Customized :Size Can be customized

Warranty : 3 years

Supply Ability : 50 Sets/Month

Oversea Warehouse&Office : Dubai,Wittingen Germany, Birmingham UK

- Advantage

- Details

- Specifications

- Videos

- Foot print

- Download

| ▄ A CNC wood lathe is a piece of equipment that you must have when you want to start a woodworking business. CNC wood turning lathes are specially designed to handle complex woodworking projects, making it easy to create different types of finished products. Providing powerful performance every time, these machines can be used to manage a wide range of engraving processes. If you want to perform detailed and comprehensive wood turning work in your workshop, then you must have a CNC wood turning lathe. They can be widely used for wood milling, wood turning and cylindrical engraving targets. |

|---|

| ▄ These machines usually consist of a steel lathe bed which is thick walled and welded strong enough to be used for different kinds of complex tasks. Steel lathe beds are also exposed to the harsh elements of vibration aging, which helps make them completely vibration-free and stress-free. In addition, they were exposed to dustless sandblasting technology, which plays a vital role in its surface treatment. This helps eliminate any signs of internal stress rigidity. Such processing makes these CNC wood lathes very powerful and sturdy and able to provide users with long-term performance for many years. The increased durability and durability of these machines greatly reduces the chance of deformation that may occur due to years of extensive use. Therefore, once you get these machines, you can rely on them to provide you with great value for your money. |

| ▄ Used for wood turning and wooden cylinder carving, it is the latest CNC wood lathe that can be used to produce garden tools, stair railing components, table legs as well as wooden handles for a wide range of agricultural activities. These machines are also suitable for designing and producing various wooden furniture components. Since the machine is operated by a computing system, it helps achieve highly precise results, every time. Unlike hand-made finished products that may involve a lot of human error, CNC wood lathes not only guarantee high accuracy and precision, but are also simple to operate. All you need to do is enter your specific dimensions and the machine does the rest for you. |

|

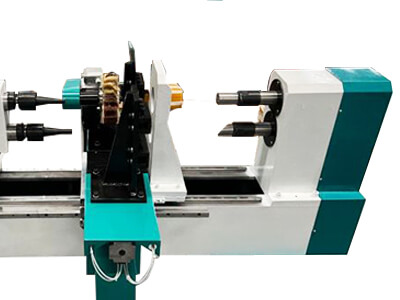

| Dual-axis automatic grinding function, one-time forming while turning, no need for secondary grinding. |

2.Pneumatic pressing cylinder, just press the switch to press the wood to tighten the wood, no need for cumbersome operations. |  |  |

|

| The super-long feeding handle saves time and effort, and can be easily slid with a slight break. With the aid of pneumatic tools, the workpiece clamping can be easily completed. |

| The two-axis four-knife design greatly increases the production efficiency while ensuring the smoothness of the workpiece |  |  |

|

| The CNC integrated cabinet includes integrated circuit systems such as CNC panels, frequency converters, and drivers, and is the core control unit of the equipment. |

BCM15030 Wood Lathe

| engraver/ Pull trough , pull and twist versatile spindle control section |

|---|

| Additional pull trough Universal rotary joint |

| Additional pull trough Universal rotary joint |

| Optional for cnc wood |

| 160mm four-jaw chuck linkage Woodworking cleaner(Vacuum cleaner) 220V constant power variable spindle control Four- exchange station automatic tool changer |

| ● 3 Years Warranty |

| Parameters | Wood Lathe | |

|---|---|---|

| Processing length(mm) | 1500 | |

| Max,swing over bed(mm) | 300 | |

| Power | 80V/50HZ | |

| Control Systems | A:Full-color 12 -inch screen built- CNC computer or B:DSP handle controller (USB) | |

| Guides and ball screws | Imported linear square rails and precision ball screw | |

| Follow rest | Rotary Centre (5CM wooden , 6CM wooden) | |

| Self-centering | Automatic centering on foot pneumatic feed | |

| Motor control | 4-pole 380 volt frequency spindle | |

| Frequency converter | Vector electronic automatic brake inverte | |

| Tailstock | Pneumatic material clamping top | |

| Tools | V -shaped steel tool are factory front , welded alloy knife | |

| Software | Control and easy to use software + basic map file | |

| Accessory tools | Random tool wrench |

- File Name Type Download

Find out More Products

EN

EN Ru

Ru

Tel:0086-15154109683

Tel:0086-15154109683

Fax:0086-15154109683

Fax:0086-15154109683

Mobile:+86 15154109683

Mobile:+86 15154109683

Skype:

Skype: