- Your are here:

- Home >

- Economic Laser Cutting Machine

Models : BCM3015F

Application :kitchen appliance, electric control box, high-resolute device, mechanical equipment, electrical equipment,auto parts like

Leadtime : 25 working days

Certificate : CE FDA

Voltage :380V

Customized :YES

Warranty : 3 Years

Supply Ability : 80 sets /Month

Oversea Warehouse&Office : Dubai , Gernmany ,United Kingdom

- Advantage

- Details

- Specifications

- Videos

- Foot print

- Download

▄ 1/BCAMCNC fiber laser cutting machinery utilizes Chinese/Germany power sources for either of its pulsed or CW (continuous wave) cutting lasers. 2/A fiber lasers power, wavelength, spot size, beam quality and power ranges are the basic parameters that modify the fibers cutting dynamics. 3/CW lasers represent the best option for thicker or various sized metals whereas pulsed lasers are typically more cost effective for cutting thin metals. 4/You can find both CO2 and fiber laser cutting machine options here admin@bcamcnc.com |

|---|

| Two machines in one One laser source and a single cutting head for two complementary processes, each with performance equal to that of a dedicated system. BCM1530F is the answer when a small footprint is the key or if production volumes do not justify two separate systems. |

| The cutting head is the most important component in a laser system, and determines both the performance and reliability of the machine. ●The best reliability on the market ●Proven laser power of up to 3000W ●The optic are 2 times less sensitive to contamination ●Cover slide needs replacing 5 times less frequently ●Only 3 consumable parts |

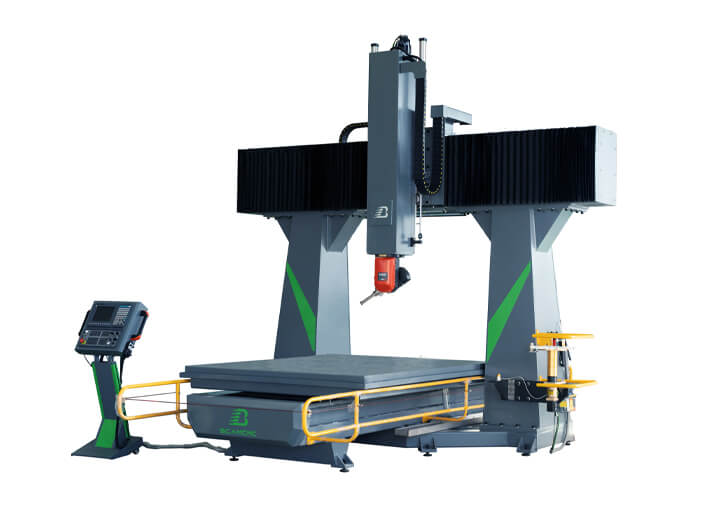

The machine body is made by High-performance steel with Integrated welding technology , This type of material has unique mechanical properties ●it has a vibration damping factor that is one hundred times higher than that of steel ●Perfect strength, accuracy and durability ●The temperature coefficient is ten times lower ●High thermal capacity ●The best basis for linear motors |  |

| Aircraft Aluminium traverse bridge The steel traverse bridge is manufactured with extreme precision to ensure that high cutting accuracy is maintained with high acceleration. Its special design eliminates Abbe Errors (linear displacement caused by a rotational error) and wobble, in order to maintain appropriate rigidity during fast cutting. Precision linear guides are positioned around the center of gravity on the base axes to provide high acceleration and accuracy.

|

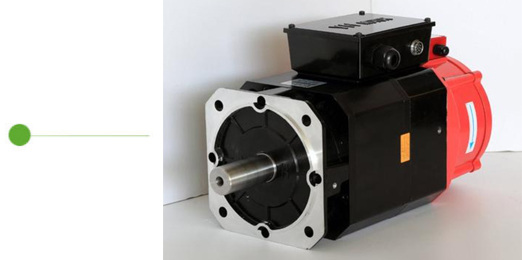

Speed, acceleration and precision Every BCAM fiber laser is equipped with Japan linear Servo motors on all movement axes. Linear motors provide high acceleration/deceleration and high dynamic accuracy. Unlike mechanical drives, linear motors do not lose energy converting rotational motor motion to linear traverse motion. |  |

| Built for speed The fiber laser is provided by RAYCUS Photonics, the undisputed chinese leader in the production of sheet metal cutting fiber lasers. RAYCUS 's innovative products are characterized by their very high energy efficiency of more than 50%, higher productivity, reduced operating costs, ease of operation and integration, and compact design. The main features of these laser sources are energy efficiency and reliability. Fiber lasers have a dynamic power range that allows the beam to focus and maintain a constant position, even after the laser power has been changed. |

Economic Fiber laser Cutting machine ( 500w-1000w )

| ● Working area: 1500*3000mm |

|---|

| ● Cypcut control system |

| ● Taiwan PMI ball screw |

| ● Taiwan ABBA gears and racks |

| ● Chinese Raycus500w- 1000w fiber laser generator (Optional : Germany Made IPG 500W-1000W) |

| ● Serrate working platform table |

| ● Wifi remote assistance |

| ● Delta servo motor and drivers WITH Japan Reducer |

| ● Location system:Red dot indicator |

| ● Au3Tech laser cutting head+Auto focus function |

| ● Taiwan Hiwin square guide rail |

| ● Japan NSK Beraring #Industrial CW6200 water chiller |

| ● Heavy duty body frame thickness,more than 2200kgs |

| ● 380V/3P/50H(Optional : 415V/3P/50H) |

| Parameters | Standard Specifications | |

|---|---|---|

| Working Area | 1500*3000mm | |

| Fiber laser generator | 1000W-4000W Raycus(Optional:Germany IPG Laser 1000W-4000W) | |

| Wavelength | 1064nm | |

| Cutting speed | 0-15m/min(depending on material and thickness) | |

| Positioning accuracy | ±0.02mm | |

| Repositioning accuracy | ±0.01mm | |

| Eauipment power | 16KW/18KW | |

| Water cooling System | Constant temperature water chiller CW62000 | |

| Power supply | 380V/3P/50Hz | |

| Location system | Red dot indicator | |

| Running Environment Temperature | -10℃~45℃ | |

| Machine Dimension | 1800*3300*1600mm |

| What materials can a Fiber laser cutting machine process? BCAM fiber laser cutting machines offer small and large companies the ability to affordably laser cut metal such as stainless, carbon steel, galvanized, and even aluminum materials. As a result companies have a great opportunity to cost effectively and efficiently laser cut highly intricate metal parts, prototypes, and customized pieces in house including: ►stainless steel ►soft steel ►Cabon steel ►aluminum ►Titanium ►brass ►copper ►thin sheet metal ►superior speed for∧5mm ►operating cost effeciency ►greater reliability ►greater service life BEST LASER TYPE FOR CUTTING METAL Today, when it comes to cutting metal there's actually over 100 different types of metals you could process.Depending on what industry you are in you probably have at least one or more types of metal you need to laser cut. FIBER or GAS (commonly CO2) laser represent the two most common processes for processing metal whether it be ferrous or non-ferrous metals. YAG or crystal laser technology has been used in the past primarily for thick metal cutting, but it is more expensive and offers a significantly shorter service life compared to CO2 and fiber laser processing. If you're wanting to laser cut thick metal (over 5mm) then CO2 will be more efficient and faster as far as straight line speeds and piercing times at the beginning of the cut. Additionally, the downside and upside is that CO2 is really only able to process stainless steel, but also organic materials like wood, acrylic, leather, fabric, stone, etc. Fiber laser beam offers a metal friendly wavelength that is metal absorbs more efficiently. The smaller spot size (1 micron wavelength), and excellent beam profile make it ideal for cutting most any metals. Most notably compared to CO2 fiber has straight line speed that's 2-3x faster when cutting thin sheet metal at 3mm or less. As far as operating costs fiber needs only about 1/3 the operating power compared to CO2. Also, fiber offers lower down time, less ongoing maintenance all translates to increased productivity. For this reason fiber has been quickly displacing the traditional CO2 laser in most metal cutting applications. |  |

|---|

Find out More Products

EN

EN Ru

Ru

Tel:0086-15154109683

Tel:0086-15154109683

Fax:0086-15154109683

Fax:0086-15154109683

Mobile:+86 15154109683

Mobile:+86 15154109683

Skype:

Skype: