- Your are here:

- Home >

- S Stone Series

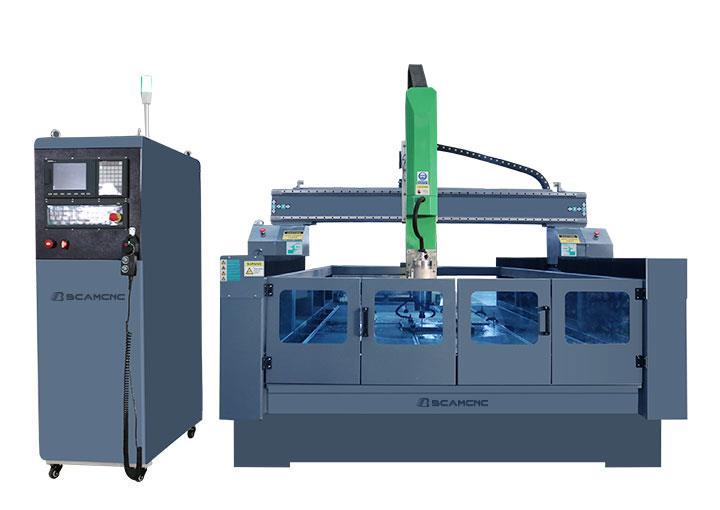

Models : BCS1325S

Application :ston, marble,granite,aluminum,wood,tombstone ,ceramic tile,bluestone,agate, bamboo

Leadtime : 10 working days

Certificate : CE ISO

Voltage :380V 3P 50HZ

Customized :YES

Warranty : 3 YEARS

Supply Ability : 50 sets/ month

Oversea Warehouse&Office : Dubai, Germany ,United Kingdom

- Advantage

- Details

- Specifications

- Videos

- Foot print

- Download

| 1.BCAM S stone engraving machine On the BCAM S stone CNC milling machine, we have created the most advanced equipment to handle various customized stone solutions. Our professional team can help you upgrade customized stone processing equipment with the accuracy of 3-axis and 5-axis CNC engraving machines. Explore the functions and advantages of one of our CNC routers, and learn how to provide customers with customized parts to reduce costs and delivery time. |

|---|

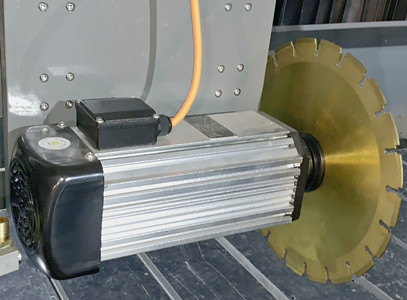

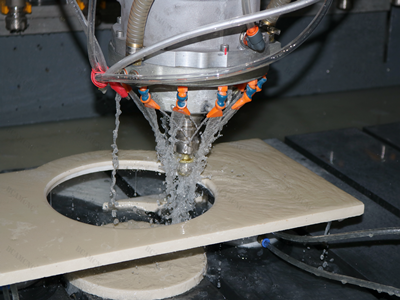

| 2.Explore the functions and advantages of one of our CNC routers, and learn how to provide customers with customized parts to reduce costs and delivery time. The function of BCAM S stone CNC milling machine These innovative machines can move on 2 axes (optionally 3 and 5 axes), so they can create the most complex shapes and shapes. The covering layer of the rubber pad allows you to handle the material without any surface scratches or excessive friction. A 1-inch water pipe will cool the blade during cutting to prevent excessive displacement. When the saw blade passes through your stone or other countertop materials, it can also cut at a fast speed. |

| 3. Benefits of BCAM S Stone Choose the leading S Stone CNC milling machine, which is an advanced machine that can quickly transform a blank into many amazing stone products. time. Before discovering how to order now, please explore the other great advantages of this saw. |

| 4.Application of CNC milling machine Our stone CNC milling machines are specially designed for stone cutting, but the functions of these dynamic machines are much more than that. Many other planers can also cut wood, steel, corrugated cardboard and plastic. Thanks to the unique core bit and water cooling system, our stone milling machine is most suitable for countertop materials. Whether you are a custom cabinet manufacturer or a licensed construction company, stone processing CNC milling machines are an excellent investment for creating your own custom pieces. BCAM Pure is an environmentally friendly water filtration system that can be used directly with your CNC milling machine. Robot lifts, jib cranes or other equipment in our factory can take your production line to the next level. |

|

| 1.Choose the leading S Stone CNC milling machine, which is an advanced machine that can quickly transform a blank into many amazing stone products. time. Before discovering how to order now, please explore the other great advantages of this saw. |

| 2.Italy HSD 13KW water cooling spindle , HSK-63F ,with Water cooling tools functions |  |  |

|

| 3. 8 Pcs Linear Tools functions and HSK-63F tools holders |

| 4.Tool senser (Automatic tool calibration pad) allows easy and accurate “Z” zero position for single and multiple tool changes through the program. This can automatically measure the distance between the tool head and the material. |  |  |

|

| 5.Our S stone cabinet lines include both frameless access construction and traditional framed inset cabinets made to your specifications. Also make perfectly for laundry rooms, home offices and other residential design projects. |

| 6.World-class servo motor and driving system ensures machine to run with fast speed and low noise |  |  |

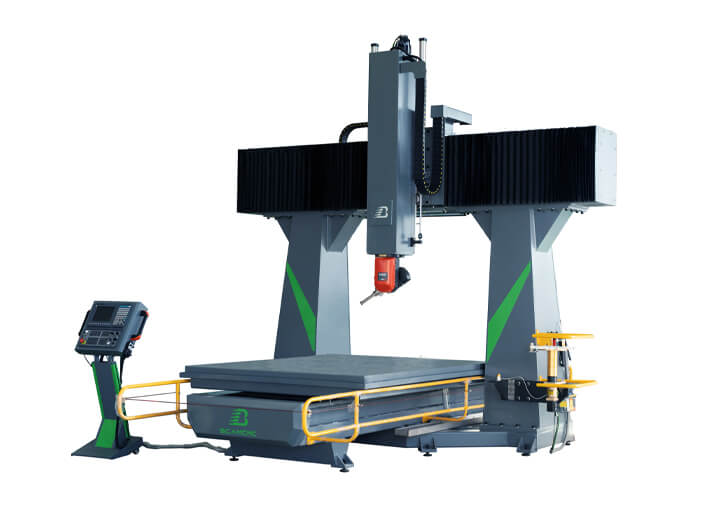

BCS2030 Stone Carving machine

| ● Working area: 2000*3000*200mm |

|---|

| ● CE standard |

| ● Italy HSD 13kw water cooling spindle (6000-24000r/min) |

| ● 30mm Heavy duty body(It can afford 3 tons ) |

| ● X ,Y axis gear transmission, Z axis Taiwan TBI ball screw transmission |

| ● Taiwan Hiwin 30 rails |

| ● T-slot and Water tank collection Table with Vacuum cup |

| ● Schneider Electronic spare parts |

| ● Automatic lubration system |

| ● Syntec from Taiwan control system |

| ● Japan Omron limit switch |

| ● Japan servo motor and drivers |

| ● Taiwan Delta Inverter |

| ● Tool height sensor |

| ● Standard box of tools |

| ● Tools cooling system |

| ● Stone 3D machining |

| Parameters | Standard Specifications BCS1325 | |

|---|---|---|

| X,Y,Z Working Area | 1300*2500*200mm|4*8ft | |

| Optional Working Area | 1300*1300*200mm|4*4ft | |

| Optional Working Area | 1500*3000*200mm|5*10ft | |

| Optional Working Area | 2000*3000*200mm|6*10ft | |

| Optional Working Area | 2000*4000*200mm|6*13ft | |

| Optional Working Area | 2000*6000*200mm|6*20ft | |

| Spindle Power | Italy HSD 13kw(optional 15kw 18kw ) water cooling spindle | |

| X,Y,Z Traveling Positioning Accuracy |  0.02/2000mm 0.02/2000mm | |

| Table Surface | T-solt table or Vacuum Cup table | |

| X,Y,Z Rail and Trasmission | X Y axis gear transmission, Z axis TaiwanTBI Ball Screw | |

| Max. Rapid Travel Rate | 30m/min | |

| Max. Working Speed | 20m/min | |

| Cutting thickness | According materials | |

| Spindle Speed | 6000-24000RPM | |

| Drive Motors | 4 sets 1500W Japan Servo motor and drivers | |

| Working Voltage | AC380v/50HZ/3 phase | |

| Command Language | G Code | |

| Operating System | Taiwan Syntec control system | |

| Interface | USB | |

| Software Compatibility | Option:Type3/Ucancam/Artcam/Solidworks,etc. | |

| Running Environment | Temperature: 0℃~45℃ Relative Humidity: 60%~90% |

| What materials can a CNC Router process?

A BCAM CNC router can machine a lot of different materials. Here listed just a few materials that can be machined 2D or 3D: ►Metals / Non-ferrous metals ►Brass ►Aluminium ►Titanium ►Noble metals such as silver, gold ►Steel and cast steel ►Wood ►Multiplex ►Plastics ►Acrylic glass ►Granite and marble Is important to note that some materials like Aluminum, require cooling during the actual milling operation. The heat generation means that chips can clog or glue the flutes of the milling machine and the milling tool breaks. Suitable coolants and lubricants can be found in the range of most CNC milling machine manufacturers. What criteria are decisive when buying a BCAM CNC Router? If you have decided to buy a BCAM CNC Mill to facilitate some work or to make special work possible, immediately one question comes to mind: “What do I have to consider when buying a CNC Router?” ►The size Before I search for a suitable manufacturer, I should have a good idea of in which size I want to edit the desired material. Because the maximum traveldictates the maximum size of my workpiece. Do I perhaps prefer to process larger workpieces? Then I should observe the maximum travel of the selected machine. ►The motor and its performance Furthermore is crucial which materials I would like to process because this depends on the required performance of the milling spindle. Soft materials such as wood consume significantly less drive power than hard metals such as steel or cast steel. Here a competent milling machine manufacturers will be happy to advise you. ►Hardness and toughness of the material Also concerning the torsional rigidity of the machine, the material to be processed is crucial. Soft materials will demand the milling machine other than hard materials, such as aluminium and steel. The harder a material is, the stiffer the CNC Router should be built. Only in this way a high accuracy in hard materials, especially metals, are guaranteed. ►Precision A CNC Router Machine should be as well adapted to the material to be machined as possible. Someone who workes mainly wood should get a one-on tailored CNC machine. The more accurately the machine fits the demands of the material, the more accurate the milling results. With these four questions I quickly find out which CNC Router is suitable for my needs: 1.What size are my workpieces to be processed? 2.What engine power do I need for my hard / soft material? 3.How hard are the materials to be processed concerning the required torsional stiffness of the machine? 4.How exactly is the selected CNC Router adapted to my desired materials / workpieces? |  |

|---|

Find out More Products

EN

EN Ru

Ru

Tel:0086-15154109683

Tel:0086-15154109683

Fax:0086-15154109683

Fax:0086-15154109683

Mobile:+86 15154109683

Mobile:+86 15154109683

Skype:

Skype: