- Your are here:

- Home >

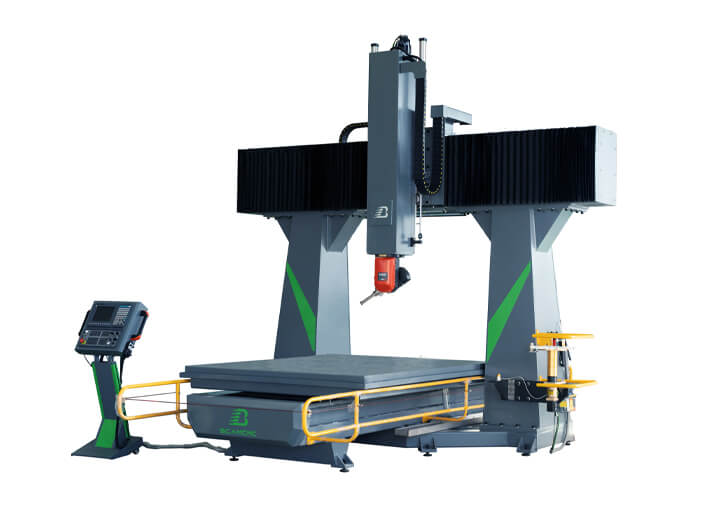

- SA Series CNC router

Models : SA Series

Application :Panel furniture, wood and wood-based materials, plastics, and non-ferrous materials

Leadtime : 20days

Certificate : CE,ISO

Voltage :380V/3P/50HZ,220V/1P/50HZ

Customized :Customizable sizes available

Warranty : 3 years

Supply Ability : 10 Sets/Month

Oversea Warehouse&Office : Dubai, Wittingen (Germany), Birmingham (UK)

- Advantage

- Details

- Specifications

- Videos

- Foot print

- Download

▄ The BCAM SA Series 4x8 CNC Router is tailored for small businesses or workshops, delivering the exceptional performance synonymous with BCAM. Leveraging advanced engineering and manufacturing, the SA Series provides exceptional versatility and seamlessly integrates into existing workflows. |

|---|

▄ The BCAM CNC router features a single-piece welded steel frame combined with an aerospace-grade aluminum gantry for exceptional rigidity and durability. The addition of cast gantry supports effectively reduces vibrations, ensuring stability during operation. Each axis is equipped with precision-engineered helical racks, delivering smooth, controlled motion and superior accuracy, enabling high-quality cutting performance |

▄ An all-new Tool and Knife System, offering both oscillating and non-oscillating capabilities, comes as a standard feature on the BCAM CNC Router, with an optional secondary knife system available. Depending on the end-user’s application requirements, spindle power options range from 4 HP to 10 HP. |

▄ The BCAM CNC Router is designed to handle a wide range of materials, including composites, foam, plastics, wood, and other industrial materials. Engineered for reliability and durability, it is built to withstand demanding applications. With a global network of service and support locations, assistance is always readily available to ensure uninterrupted operation. |

|

| Richauto A11 DSP controller Optional:March3 March4(Ethernet Controller), Weihong DSP controller, Taiwan Syntec, NCStudio 53C, 95A, also with Wifi controller. |

Auto lubrication system: one touch can finish periodic maintenance easily. |  |  |

|

| Comes with 3.5kW Spindle and Inverter with air cooling system. 110V or 220V or 380V available. |

| Anti-collision emergency stop switch protection for workers,Reduce mechanical damage by 30% |  |  |

|

| Manual tool setting block |

BCM SA Series Proffesional CNC Router for Woodworking and Signmaking

| ● Working area: 1300*2500*200mm|4′*8′ |

|---|

| ● CE standard |

| ● 3.5kw Air cooling spindle |

| ● Heavy duty frame |

| ● X ,Y axis gear transmission, Z axis ball screw transmis |

| ● High precision 25 rails |

| ● Vacuum table+T-solt |

| ● Schneider Electronic spare parts |

| ● Automatic lubrication system |

| ● Inner cabinet |

| ● Rich auto A11 control system |

| ● Japan Omron limit switch |

| ● High torque stepper motor and drivers |

| ● Fuling Inverter 3.7kw |

● 3.0kw double dust collector +Dust collector pipe+Dust collec |

| ● Tool height sensor |

| ● Standard box of tool |

| Parameters | SA Serie cnc router 4x8 cnc BCM1325SA | |

|---|---|---|

| X,Y,Z Working Area | 1300*2500*200mm|4*8ft | |

| Optional Working Area | 1300*1300*200mm|4*4ft | |

| Optional Working Area | 1500*3000*200mm|5*10ft | |

| Optional Working Area | 2000*3000*200mm|6*10ft | |

| Optional Working Area | 2000*4000*200mm|6*13ft | |

| Optional Working Area | 2000*6000*200mm|6*20ft | |

| Spindle Power | 3.5kw air cooling spindle | |

| X,Y,Z Traveling Positioning Accuracy |  0.03/2000mm 0.03/2000mm | |

| Table Surface | Vacuum table+T-solt table | |

| X,Y,Z Rail and Trasmission | X Y axis gear transmission, Z axis Ball Screw | |

| Max. Rapid Travel Rate | 40m/min | |

| Max. Working Speed | 30m/min | |

| Cutting thickness | According materials | |

| Spindle Speed | 6000-24000RPM | |

| Drive Motors | 4 sets High Torque stepper motor and drivers | |

| Working Voltage | AC220v0r380v/50HZ/3 phase,220v/1phase/50hz | |

| Command Language | G Code | |

| Operating System | Richauto A11 DSP control system | |

| Interface | USB | |

| Software Compatibility | Option:Type3/Ucancam/Alphacam/Solidworks,etc. | |

| Running Environment | Temperature: -20℃~45℃ Relative Humidity:5%~75% |

| What materials can a CNC Router process? A BCAM CNC router can machine a lot of different materials. Here listed just a few materials that can be machined 2D or 3D: ►Soft metals / Non-ferrous metals ►Brass ►Aluminium ►Titanium ►Noble metals such as silver, gold ►Wood ►Multiplex ►Plastics ►Acrylic glass ►Granite and marble Is important to note that some materials like Aluminum, require cooling during the actual milling operation. The heat generation means that chips can clog or glue the flutes of the milling machine and the milling tool breaks. Suitable coolants and lubricants can be found in the range of most CNC milling machine manufacturers. What criteria are decisive when buying a BCAM CNC Router? If you have decided to buy a BCAM CNC Mill to facilitate some work or to make special work possible, immediately one question comes to mind: “What do I have to consider when buying a CNC Router?” ►The size Before I search for a suitable manufacturer, I should have a good idea of in which size I want to edit the desired material. Because the maximum traveldictates the maximum size of my workpiece. Do I perhaps prefer to process larger workpieces? Then I should observe the maximum travel of the selected machine. ►The motor and its performance Furthermore is crucial which materials I would like to process because this depends on the required performance of the milling spindle. Soft materials such as wood consume significantly less drive power than hard metals such as steel or cast steel. Here a competent milling machine manufacturers will be happy to advise you. ►Hardness and toughness of the material Also concerning the torsional rigidity of the machine, the material to be processed is crucial. Soft materials will demand the milling machine other than hard materials, such as aluminium and steel. The harder a material is, the stiffer the CNC Router should be built. Only in this way a high accuracy in hard materials, especially metals, are guaranteed. ►Precision A CNC Router Machine should be as well adapted to the material to be machined as possible. Someone who workes mainly wood should get a one-on tailored CNC machine. The more accurately the machine fits the demands of the material, the more accurate the milling results. With these four questions I quickly find out which CNC Router is suitable for my needs: 1.What size are my workpieces to be processed? 2.What engine power do I need for my hard / soft material? 3.How hard are the materials to be processed concerning the required torsional stiffness of the machine? 4.How exactly is the selected CNC Router adapted to my desired materials / workpieces? |  |

|---|

- File Name Type Download

Find out More Products

EN

EN Ru

Ru

Tel:0086-15154109683

Tel:0086-15154109683

Fax:0086-15154109683

Fax:0086-15154109683

Mobile:+86 15154109683

Mobile:+86 15154109683

Skype:

Skype: