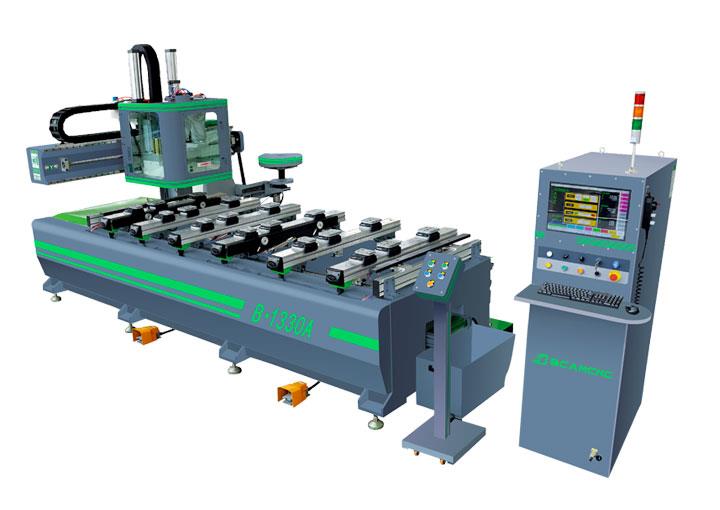

Models : BCM1325F

Application :woodkworking ,furniture ,advertising, side hole making, panel furniture making

Leadtime : 25 working days

Certificate : CE ISO

Voltage :380V

Customized :available

Warranty : 3 years

Supply Ability : 20 sets /month

Oversea Warehouse&Office : Dubai , Gernmany ,United Kingdom

- Advantage

- Details

- Specifications

- Videos

- Foot print

- Download

| 1、We're manufacturer of CNC routers with over 10 years experience. |

|---|

| 2、All our machines are made in strict accordance to ISO & CE & SGS certificate with premium quality and competitive price. |

| 3、Our sales& service network has covered all dometic major cities and overseas markets, such as the USA, European, Southeast Asia, Middle East etc. |

|

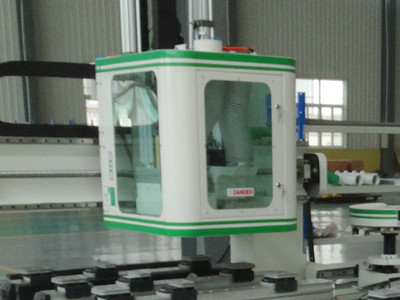

| The innovative German Schmalz PTP workbench is universal,The designprovides great flexibility and quick setup. it Protected by proprietary patents Used to quickly lock parts of any shape And size, greatly reducing the settings time. Quick change coupling system Guaranteed quick and easy replacement Vacuum devices and U niclamps are used Lock down narrow and particularly thick fragments |

| ISO 30 or HSK F63 electrospindle, 13.2 kW AND Boring Head 9+3+1 are designed and manufactured for BCAM by Italy HSD |  |  |

|

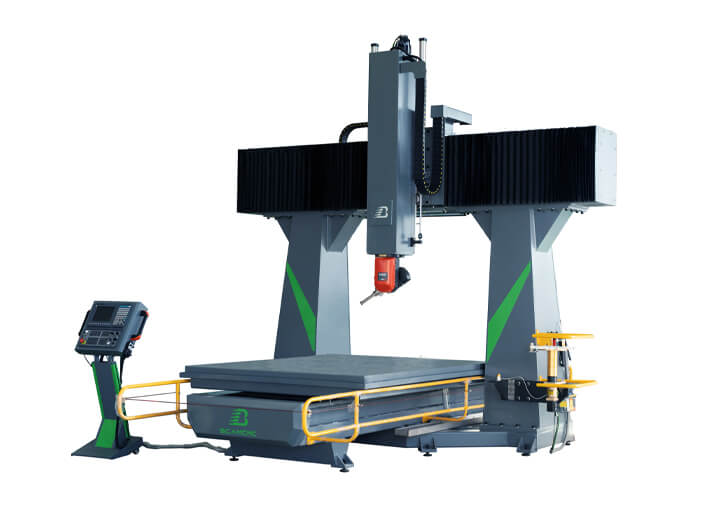

| AGGREGATES TO PERFORM ANY MACHINING which can be continuously positioned over 360° by NC, can house aggregates used to carry out specific machining operations (pocketing for locks, hinge housings, deep horizontal bores, edge trimming, etc.). Horizontal motor with two outlets for the routing of locks and horizontal machining operations. |

| Pod and Rail Vacuum table It is divided in 2 work zones.This machine is mainly used to make solid wood door or for panel processing , Eesy to Loading and Unloading |  |  |

|  | Automatic Tool Change: BCM1325F series is a cnc router designed by BCAM for Carousel tools changer 8 Tools or more upon request. This series is more automatic than BCM1325C manual tool change series. It is faster than BCM1325D series tool change, eliminating manual The cumbersome tool change shortens the tool change time and makes the cnc router more precise. |

| This aluminum protrusion located at the end of the machine helps the operator to slide the workpiece on with ease. |  |  |

|  | Spindle and Drilling System: BCM1325F selects Italian HSD air-cooled spindle, power range:9.5KW-15KW.high-power and high-speed spindles for optimum processing of rigid sheet materials. |

BCM1325F CNC wood machine for door and windows

| ● Working area: 1300*3000*200mm|4′*8′ |

|---|

| ● 9.5KW Italy HSD air cooling spindle |

| ● Italy drilling bank 9V+4H+2S |

| ● Japan Yaskawa 850W servo motors and drivers |

| ● Active safety system |

| ● Taiwan Syntec control system |

| ● X,Y axis Germany helical gear and rack transmission |

| ● German Schmalz PTP table |

| ● France Schneider electrical components |

| ● Japan Omron limited switch |

| ● Z axis Taiwan TBI ball screw |

| ● Taiwan Delta inverter 11kw Taiwan Apext reducer |

| ● Heavy duty body 8mm thickness |

| ● Taiwan HIVIN 30mm square guide rails |

| ● 8 pcs ISO30 tool holders,Air cylinder |

| ● Vacuum table |

| ● 7.5KW oil-less vacuum pump |

| ● Oil lubrication system |

| ● Hydualic lifter and belt conveyor |

| ● Tool setting gauge |

| ● Standard box of tools |

| Parameters | Standard Specifications BCM1325F | |

|---|---|---|

| X,Y,Z Working Area | 1300*3000*200mm|4*8ft | |

| Optional Working Area | 1300*3000*200mm|4*8ft | |

| Optional Working Area | 1500*3000*200mm|5*8ft | |

| Optional Working Area | ||

| Spindle Power | 9.5kw Italy air cooling spindle(Optional : 11kw 13kw) | |

| X,Y,Z Traveling Positioning Accuracy |  0.01/2000mm 0.01/2000mm | |

| Table Surface | Vacuum + Pop-up Pins Table | |

| X,Y,Z Rail and Trasmission | X Y axis gear transmission, Z axis TaiwanTBI Ball Screw | |

| Max. Rapid Travel Rate | 50m/min | |

| Max. Working Speed | 40m/min | |

| Cutting thickness | According materials | |

| Spindle Speed | 6000-24000RPM | |

| Drive Motors | Japanese Yaskawa Servo motor and Drivers | |

| Working Voltage | AC380v/50HZ/3 phase | |

| Command Language | G Code, M Code | |

| Operating System | Taiwan Syntec control system | |

| Interface | USB,NETWORK,WIFI | |

| Software Compatibility | Option:Alphacam/solidworks/AutoCAD,etc. | |

| Running Environment | Temperature: 0℃~45℃ Relative Humidity: 30%~75% |

| What materials can a CNC Router process?

A BCAM CNC router can machine a lot of different materials. Here listed just a few materials that can be machined 2D or 3D: ►Metals / Non-ferrous metals ►Brass ►Aluminium ►Titanium ►Noble metals such as silver, gold ►Steel and cast steel ►Wood ►Multiplex ►Plastics ►Acrylic glass ►Granite and marble Is important to note that some materials like Aluminum, require cooling during the actual milling operation. The heat generation means that chips can clog or glue the flutes of the milling machine and the milling tool breaks. Suitable coolants and lubricants can be found in the range of most CNC milling machine manufacturers. What criteria are decisive when buying a BCAM CNC Router? If you have decided to buy a BCAM CNC Mill to facilitate some work or to make special work possible, immediately one question comes to mind: “What do I have to consider when buying a CNC Router?” ►The size Before I search for a suitable manufacturer, I should have a good idea of in which size I want to edit the desired material. Because the maximum traveldictates the maximum size of my workpiece. Do I perhaps prefer to process larger workpieces? Then I should observe the maximum travel of the selected machine. ►The motor and its performance Furthermore is crucial which materials I would like to process because this depends on the required performance of the milling spindle. Soft materials such as wood consume significantly less drive power than hard metals such as steel or cast steel. Here a competent milling machine manufacturers will be happy to advise you. ►Hardness and toughness of the material Also concerning the torsional rigidity of the machine, the material to be processed is crucial. Soft materials will demand the milling machine other than hard materials, such as aluminium and steel. The harder a material is, the stiffer the CNC Router should be built. Only in this way a high accuracy in hard materials, especially metals, are guaranteed. ►Precision A CNC Router Machine should be as well adapted to the material to be machined as possible. Someone who workes mainly wood should get a one-on tailored CNC machine. The more accurately the machine fits the demands of the material, the more accurate the milling results. With these four questions I quickly find out which CNC Router is suitable for my needs: 1.What size are my workpieces to be processed? 2.What engine power do I need for my hard / soft material? 3.How hard are the materials to be processed concerning the required torsional stiffness of the machine? 4.How exactly is the selected CNC Router adapted to my desired materials / workpieces? |  |

|---|

Find out More Products

EN

EN Ru

Ru

Tel:0086-15154109683

Tel:0086-15154109683

Fax:0086-15154109683

Fax:0086-15154109683

Mobile:+86 15154109683

Mobile:+86 15154109683

Skype:

Skype: