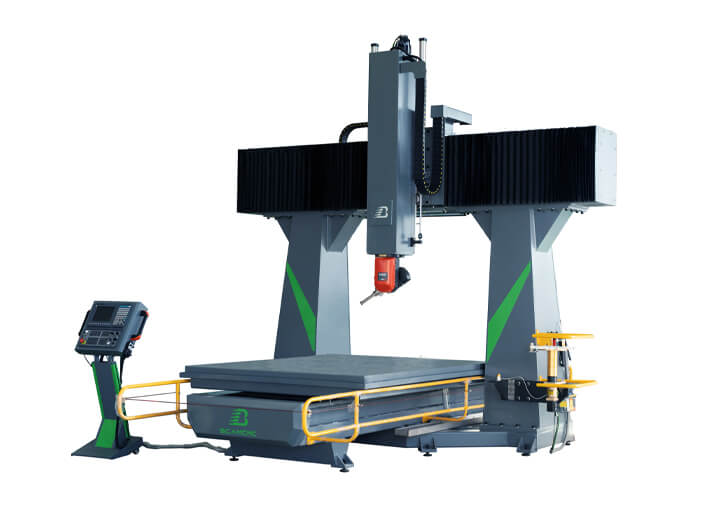

Models : E Series

Application :Panel Funiture,Wood&Wood based materials,Plastic&Non ferrous Metarials

Leadtime : 15-20days

Certificate : CE,ISO

Voltage :380V/3P/50HZ,220V/1P/50HZ

Customized :Size Can be customized

Warranty : 3 years

Supply Ability : 10 Sets/Month

Oversea Warehouse&Office : Dubai,Wittingen Germany, Birmingham UK

- Advantage

- Details

- Specifications

- Videos

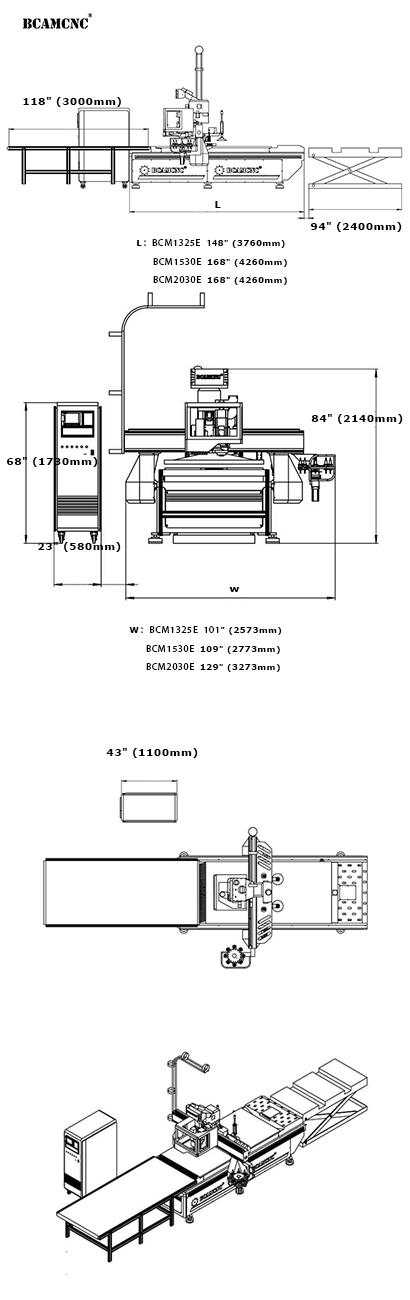

- Foot print

- Download

| ▄ The E series cnc router furniture making machine has an automatic loading panel lift system, an automatic advance unloading conveyer table, an extremely strong welded steel beam frame with a rotary tool changer on the gantry, 13 HP router spindle and a 9 spindle drilling head. Like all CNC built by BCAM the BCM1325E offers better performance, quality, components and features than any competitive machine in its class. The E series is extremely fast and allows the operator to simply stand at the end of the unload table and remove cut parts as they unload from the machine. |

|---|

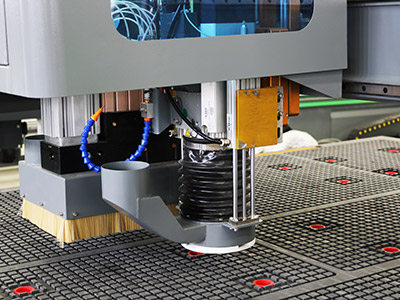

| ▄ The loading lift system allows the operator to load a lift of panels at one time on a heavy steel platform with automatic rise indexing. Using a vacuum cup loading system the machine pulls each panel onto the CNC table for machining while at the same time unloads the previous machined parts and vacuums the machining table clean at the same time. The lift will automatically index the next panel to the correct height for the four 6” vacuum cups to pick it up for the next machining process. The machined parts are pushed onto an automatic advancing conveyer table which senses the panels to be removed. Once the parts at the end of the conveyer are removed by the operator the conveyer will automatically advance the next cut parts to the end of the table and wait for the operator to remove them. An optional printer is available to label parts for tracking throughout the customer’s factory. |

| ▄ The base of the machine is a 6000 pound very heavy duty welded steel beam floor model frame. The phenolic vacuum table is then mounted to the steel frame for an excellent working surface and comes with an MDF spoilboard machined at the factory and bolted down to the table. We use plastic bolts to ensure no damage to cutters from contact. The spoilboard is bolted to the table to ensure stability during the loading and unloading process. |

|

| The control system of BCM1325E adopts the more advanced Taiwan Syntec system, which is widely acclaimed internationally and can perfectly control 3axis, 4, 5, 6, 8axis. The Syntec system can work online and WiFi links, greatly increasing the intelligence of the device. |

| BCM1325E selects Italian HSD air-cooled spindle ES951 9.5KW . Choose from manual, quick-release, high-power and high-speed spindles for optimum processing of rigid sheet materials. |  |  |

|

| The original active protection system, also known as the “anticollision emergency stop switch”, has active protection for workers’ safety during the working process of the machine. At the same time, it has a system to automatically save thebreakpoint, and after the alarm is manually released, the engraving machine can continue to work |

| BCM1325E series is a cnc router designed by BCAM for automatic disc changer. This series is more automatic than BCM1325A manual tool change series. It is faster than BCM1325C series tool change, eliminating manual The cumbersome tool change shortens the tool change time and makes the cnc router more precise. |  |  |

|

| Auto lubricating system, one touch can finish periodic maintenance easily. |

| Panel Loading system with scissor lift and automatic panel alignment. The system ease of use ensures long term reliability .also Moving the panel with dynamic vacuum sunction cup loading system , A solution that adats to all sureface types. |  |  |

|

| The country's first dust-free vacuum system is inspired by the “Typhoon” cyclone. Our French engineer, Mr Ness, studied this technology for three years and finally developed it successfully which has been perfectly applied into our products, which is now a BCAM patent courtesy of our French engineer. After the improvement by Mike, our Design Director, it has been applied to our S, C, D and E series equipment. The beautiful design and excellent performance have won praise from many customers. More and more customers have seen the revolutionary vacuum design in the industry, and some of them traveled from far to purchase BCAM engraving machines. |

BCM1325E Loading and Unloading system

| ● Working area: 1300*2500*200mm|4′*8′ |

|---|

| ● CE standard |

| ● Panel Loading and Unloading system (Automatic ) |

| ● Italian HSD 9.5KW(12HP) Electrospindle with 12-position Automatic Tool Changer(ISO30) |

| ● 15mm Heavy duty body |

| ● Active protection safety system |

| ● Helical rack and pinion drivers on X and Y axis, Z axis Taiwan TBI ball screw transmission |

| ● 25mm Heavy-duty Hiwin HG Series linear bearing |

| ● Vacuum table+T-solt |

| ● Taiwan Syntec Control system (4 Axis) |

| ● Japan Yaskawa servo motor and drivers system |

| ● Delta brand VFD-B variable frenquency drive |

| ● 12 Position Automatic Tool Changer |

| ● Tool Cone Holder-for east bit changing |

| ● Solid State limit switches |

| ● Airtech pro Dust-free extraction hood |

| ● 3 Years Warranty |

| Parameters | cnc router furniture making Machine BCM1325E Plus | |

|---|---|---|

| X,Y,Z Working Area | 1300*2500*200mm|4*8ft | |

| Optional Working Area | 1300*1300*200mm|4*4ft | |

| Optional Working Area | 1500*3000*200mm|5*10ft | |

| Optional Working Area | 2000*3000*200mm|7*10ft | |

| Spindle Power | 9kw Italy HSD air cooling spindle | |

| X,Y,Z Traveling Positioning Accuracy |  0.01/2000mm 0.01/2000mm | |

| Table Surface | Vacuum table | |

| X,Y,Z Rail and Trasmission | X Y axis gear transmission, Z axis TaiwanTBI Ball Screw | |

| Max. Rapid Travel Rate | 80m/min | |

| Max. Working Speed | 45m/min | |

| Cutting thickness | According materials | |

| Spindle Speed | 24000r/min | |

| Drive Motors | 4 sets 750w Yaskawa servo motor and drivers | |

| Working Voltage | AC380v/50HZ/3 phase | |

| Command Language | G Code | |

| Operating System | Taiwan Syntec 6MB control system | |

| Interface | USB,NETWORK | |

| Software Compatibility | Option:Alpacam/Carblnets Version/BCAMNESTTING/Solidworks,etc. | |

| Running Environment | Temperature: 0℃~45℃ Relative Humidity: 30%~75% |

| What materials can a CNC Router process?

A BCAM CNC router can machine a lot of different materials. Here listed just a few materials that can be machined 2D or 3D: ►Soft metals / Non-ferrous metals ►Brass ►Aluminium ►Titanium ►Noble metals such as silver, gold ►Wood ►Multiplex ►Plastics ►Acrylic glass ►Granite and marble Is important to note that some materials like Aluminum, require cooling during the actual milling operation. The heat generation means that chips can clog or glue the flutes of the milling machine and the milling tool breaks. Suitable coolants and lubricants can be found in the range of most CNC milling machine manufacturers. What criteria are decisive when buying a BCAM CNC Router? If you have decided to buy a BCAM CNC Mill to facilitate some work or to make special work possible, immediately one question comes to mind: “What do I have to consider when buying a CNC Router?” ►The size Before I search for a suitable manufacturer, I should have a good idea of in which size I want to edit the desired material. Because the maximum traveldictates the maximum size of my workpiece. Do I perhaps prefer to process larger workpieces? Then I should observe the maximum travel of the selected machine. ►The motor and its performance Furthermore is crucial which materials I would like to process because this depends on the required performance of the milling spindle. Soft materials such as wood consume significantly less drive power than hard metals such as steel or cast steel. Here a competent milling machine manufacturers will be happy to advise you. ►Hardness and toughness of the material Also concerning the torsional rigidity of the machine, the material to be processed is crucial. Soft materials will demand the milling machine other than hard materials, such as aluminium and steel. The harder a material is, the stiffer the CNC Router should be built. Only in this way a high accuracy in hard materials, especially metals, are guaranteed. ►Precision A CNC Router Machine should be as well adapted to the material to be machined as possible. Someone who workes mainly wood should get a one-on tailored CNC machine. The more accurately the machine fits the demands of the material, the more accurate the milling results. With these four questions I quickly find out which CNC Router is suitable for my needs: 1.What size are my workpieces to be processed? 2.What engine power do I need for my hard / soft material? 3.How hard are the materials to be processed concerning the required torsional stiffness of the machine? 4.How exactly is the selected CNC Router adapted to my desired materials / workpieces? |  |

|---|

Find out More Products

EN

EN Ru

Ru

Tel:0086-15154109683

Tel:0086-15154109683

Fax:0086-15154109683

Fax:0086-15154109683

Mobile:+86 15154109683

Mobile:+86 15154109683

Skype:

Skype: