- Your are here:

- Home >

- 5 Axis Stone Cutting Machine

Models : BCMS 2035

Application :ston, marble,granite,aluminum,wood,tombstone ,ceramic tile,bluestone,agate, bamboo

Leadtime : 10 working days

Certificate : CE ISO

Voltage :380V 3P 50HZ

Customized :YES

Warranty : 3 YEARS

Supply Ability : 50 sets/ month

Oversea Warehouse&Office : Dubai, Germany ,United Kingdom

- Advantage

- Details

- Specifications

- Videos

- Foot print

- Download

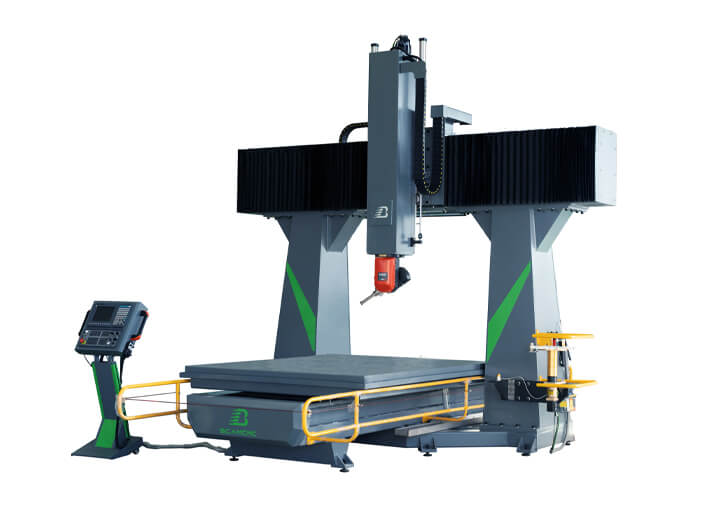

| BCMS2035-500 11kw is the new generation multi-function processing machine which is associated to be designed and manufactured. With pattern operation and advanced control system and synchronous CNC control system, the machine can be easily operated easily without knowing complicated CNC knowledge. |

|---|

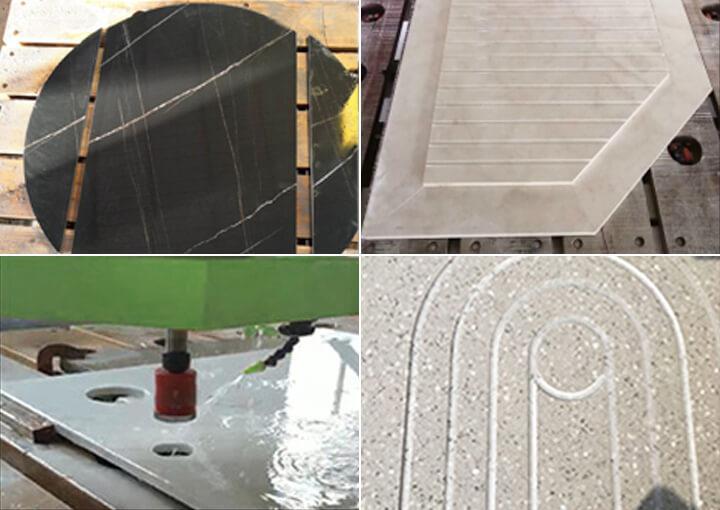

| This machine can be used to realize some advanced functions like: Camera function --- positioning typesetting, automatic measurement of plate thickness and tool size, the machine head can be rotated 360 degrees. Cutting, edging, chamfering, digging and other multi-functional integration, the intelligent operating system is simple and easy to learn, high-quality motor, high precision and fast speed. Horizontal, vertical, arc, round any angle, shape cutting. The machine head can move and rotate freely. In addition to cutting shape, it can also be used for large plates, with a 45-degree chamfer, open basin hole, stove hole, slash cutting. Suitable for quartz stone, rock slab, artificial stone, granite, marble and other large, medium and small stone decoration projects. |

| Horizontal, vertical, arc, round any angle, shape cutting. The machine head can move and rotate freely. In addition to cutting shape, it can also be used for large plates, with a 45-degree chamfer, open basin hole, stove hole, slash cutting. Suitable for quartz stone, rock slab, artificial stone, granite, marble and other large, medium and small stone decoration projects. |

| Horizontal, vertical, arc, round any angle, shape cutting. The machine head can move and rotate freely. In addition to cutting shape, it can also be used for large plates, with a 45-degree chamfer, open basin hole, stove hole, slash cutting. Suitable for quartz stone, rock slab, artificial stone, granite, marble and other large, medium and small stone decoration projects. |

|

| 1:Increase Dust-Free vacuum efficiency by 80%, No1 revolutionary dust vacuum designin the industry and Have won praise frommany customers. |

2:2D and 3D processing with router and knife tools, Compatible with standard G-Code based 99% CAD/CAM software programs |  |  |

|

| 3:The use of high-performance computer system control, simple operation, high efficiency. |

4:"600℃ Annealing treatment continued 24 hours 10 Years Machine bed Not deformed, 100% drilling hole by highest accuracy 5 Axis milling machine" |  |  |

|

| 5:Photo layout positioning, automatic measurement of plate thickness and tool siz |

BCS2035 Stone Carving machine

| ● Working area: 3500*2000mm |

|---|

| ● CE standard |

| ● Italy HSD 13kw water cooling spindle (6000-24000r/min) |

| ● 30mm Heavy duty body(It can afford 3 tons ) |

| ● X ,Y axis gear transmission, Z axis Taiwan TBI ball screw transmission |

| ● Taiwan Hiwin 30 rails |

| ● T-slot and Water tank collection Table with Vacuum cup |

| ● Schneider Electronic spare parts |

| ● Automatic lubration system |

| ● Syntec from Taiwan control system |

| ● Japan Omron limit switch |

| ● Japan servo motor and drivers |

| ● Taiwan Delta Inverter |

| ● Tool height sensor |

| ● Standard box of tools |

| ● Tools cooling system |

| ● Stone 3D machining |

| Parameters | Standard Specifications BCMS2035 | |

|---|---|---|

| X,Y,Z Working Area | 3500*2000*260MM | |

| Programming Method | CAD & Manual | |

| A AXIS Working Stroke | 360° Free Rotation | |

| B AXIS Working Stroke | Auto 0-90 degree chamfer | |

| X,Y,Z Traveling Positioning Accuracy / Accufacy | ±0.8/2000mm / 0.2 | |

| Main Spindle Motor Power | 11kw 3P/380V*50HZ , 1000-6000R/min | |

| X.Y.Z transmisstion | X Y axis gear transmission, Z axis TaiwanTBI Ball Screw | |

| Max. Rapid Travel Rate | 35m/min | |

| Max Cutting Thickness | 100mm | |

| Working Table siz | 3500*2000mm | |

| Overall Size of Machine | 6350*4950*3450MM (L*W*H) | |

| Weight Total | 6800kg | |

| Blade size | 500mm | |

| Command Language | G Code |

| What materials can a CNC Router process?

A BCAM CNC router can machine a lot of different materials. Here listed just a few materials that can be machined 2D or 3D: ►Metals / Non-ferrous metals ►Brass ►Aluminium ►Titanium ►Noble metals such as silver, gold ►Steel and cast steel ►Wood ►Multiplex ►Plastics ►Acrylic glass ►Granite and marble Is important to note that some materials like Aluminum, require cooling during the actual milling operation. The heat generation means that chips can clog or glue the flutes of the milling machine and the milling tool breaks. Suitable coolants and lubricants can be found in the range of most CNC milling machine manufacturers. What criteria are decisive when buying a BCAM CNC Router? If you have decided to buy a BCAM CNC Mill to facilitate some work or to make special work possible, immediately one question comes to mind: “What do I have to consider when buying a CNC Router?” ►The size Before I search for a suitable manufacturer, I should have a good idea of in which size I want to edit the desired material. Because the maximum traveldictates the maximum size of my workpiece. Do I perhaps prefer to process larger workpieces? Then I should observe the maximum travel of the selected machine. ►The motor and its performance Furthermore is crucial which materials I would like to process because this depends on the required performance of the milling spindle. Soft materials such as wood consume significantly less drive power than hard metals such as steel or cast steel. Here a competent milling machine manufacturers will be happy to advise you. ►Hardness and toughness of the material Also concerning the torsional rigidity of the machine, the material to be processed is crucial. Soft materials will demand the milling machine other than hard materials, such as aluminium and steel. The harder a material is, the stiffer the CNC Router should be built. Only in this way a high accuracy in hard materials, especially metals, are guaranteed. ►Precision A CNC Router Machine should be as well adapted to the material to be machined as possible. Someone who workes mainly wood should get a one-on tailored CNC machine. The more accurately the machine fits the demands of the material, the more accurate the milling results. With these four questions I quickly find out which CNC Router is suitable for my needs: 1.What size are my workpieces to be processed? 2.What engine power do I need for my hard / soft material? 3.How hard are the materials to be processed concerning the required torsional stiffness of the machine? 4.How exactly is the selected CNC Router adapted to my desired materials / workpieces? |  |

|---|

- File Name Type Download

Find out More Products

EN

EN Ru

Ru

Tel:0086-15154109683

Tel:0086-15154109683

Fax:0086-15154109683

Fax:0086-15154109683

Mobile:+86 15154109683

Mobile:+86 15154109683

Skype:

Skype: