- Your are here:

- NEWS

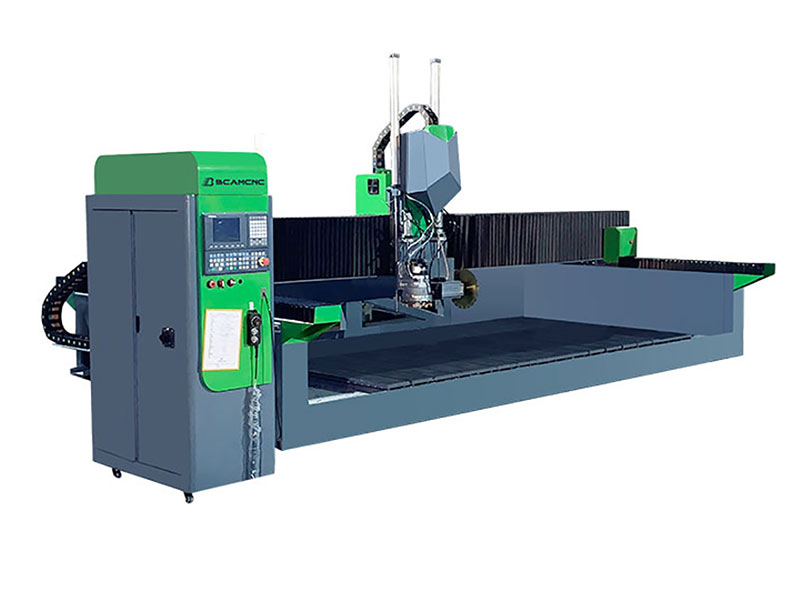

The methods you need to master when using a stone CNC router

Upload to:05-08 2021

Upload to:05-08 2021

When using a stone CNC router for engraving, if you want to ensure the accuracy of engraving, you must pay attention to the method of use, so as not to cause equipment failure due to improper operation. In addition, the usual daily maintenance work is also to be done, so that the equipment can be used for a long time. So what methods do you need to master when using a stone CNC router? Let BCAM CNC introduce to you .

The methods

1. Before starting the stone CNC router, make sure that all connections between the machine tool and the computer are normal, and then turn on the power supply of the machine tool and the computer.

2. After opening the control system, select the return to mechanical origin menu. The machine tool will automatically return to the mechanical origin and correct the coordinate system of the system. In some cases, after the previous normal shutdown, the customer will start the machine again and continue the previous use without performing a mechanical reset. When exiting normally, the system will save the current coordinate information. At the same time, if the customer confirms that the location is correct, it may not be available.

3. Before processing, customers usually have to load the required processing program, otherwise, some functions related to automatic processing will be invalid. Select the Open menu to open a Windows standard file usage dialog box, from which you can select the drive, path and file name of the file to be opened. After clicking the Open button, the handler is loaded into the system.

4. Confirm the origin of the workpiece, manually move the X and Y directions to the expected origin position on the workpiece, select the current point as the origin menu of the workpiece, or clear the coordinate value of the position in the coordinate window, so that the coordinate value of this position can be used when the processing program is executed. Position as the starting point for processing.

About maintenance

1. Stabilize the voltage. Ensuring a stable voltage is the first principle to ensure the electrical components of the equipment. The stone engraving machine has protective measures such as leakage protection switch and thermistor. If the voltage is unstable or the temperature is too high, the device will sound an alarm, which will ensure your health and create a good office environment.

2. Strengthen lubrication. Guide rails, lead screws and other accessories are the track during operation, and timely injection of lubricating oil is conducive to the smooth running of the driving track.

3. Cooling water temperature. The cutting force of stone carving is large, and the cooling condition of the spindle and the cutter depends on the water temperature. A good cooling effect is conducive to the service life of the spindle and the cutter, avoiding excessive water temperature in summer and preventing freezing in winter.

4. Choose a good knife. The consumables of stone carving are basically knives, good knives can be used continuously for a long time. If the tool is changed frequently, the tool post and spindle will be affected. The frequent start and stop of the equipment will be inconsistent, which will also affect the equipment.

5. Lighten the load. The equipment is used to process materials, not to place a platform. During use, prevent heavy objects from accumulating on the equipment beam. Caring for your equipment is your guarantee for long-term use.

6. Check carefully and clean and hygienic. After intense work on time or for a long time, ensure the cleanliness of the equipment, prevent the accumulation of sludge, check the equipment, and effectively extend the service life of the equipment.

In order to ensure that the stone CNC router can better perform the engraving work, in order to give full play to the role of the equipment, it is necessary to do daily cleaning work and clean up the dust and dirt on the equipment in time, so as to ensure the accuracy of the equipment and ensure that the equipment can fully play its role. The above are the methods you need to master when using a stone CNC router. If you want to know more machine information, please pay attention to our website.

- Previous : Common types of woodworking CNC routers

- Next : Automatic loading and unloading machining center

EN

EN Ru

Ru