- Your are here:

- NEWS

Automatic loading and unloading machining center

Upload to:05-10 2021

Upload to:05-10 2021

At present, the industry is developing more and more, and the supply of furniture is in short supply. With the changes in people’s living conditions, private customization in all walks of life is gradually becoming commonplace. So how do custom-made furniture cabinets are produced? What kind of CNC router is used for production? Today, BCAM will introduce to you the CNC router of the loading and unloading processing center.

What is an automatic loading and unloading machining center?

The automatic or semi-automatic mechanical device that sends the workpiece to be processed to the processing position on the machine tool and removes the processed workpiece from the processing position is called an automatic loading and unloading machining center, also known as an automatic workpiece loading and unloading device.

The automatic unloading mechanism of most machine tool loading and unloading devices is relatively simple, or the automatic loading mechanism has the function of automatic unloading, so the loading and unloading device of the machine tool is also often referred to as the loading device. It is an integral part of the automatic machine tool. After the semi-automatic machine tool is equipped with a loading and unloading device, the processing cycle can be continuously and automatically carried out to become an automatic machine tool. The machine tool loading and unloading device is used for semi-automatic machine tools with high efficiency, short maneuvering time and frequent workpiece loading and unloading, which can significantly improve production efficiency and reduce physical labor. The loading and unloading device of the machine tool is also an indispensable auxiliary device for the automatic production line.

Performance characteristics of automatic loading and unloading machining center.

1. The automatic loading and unloading machining center adopts imported linear square guide rails, double-row and four-row ball sliders, with large bearing capacity, stable operation, high precision and long life. Imported ball screw has high precision and accurate cutting.

2. Taiwan's new-generation high-performance industrial control system, with excellent and stable quality, good maintainability, can control the completion of multi-level 3D processing, and can perform fast and smooth three-dimensional processing, engraving and cutting.

3. The main shaft motor adopts Italian air-cooled main shaft, which has high precision, high speed, long life and stable operation. Give full play to the superior performance of this machine.

4. Japan Yaskawa servo drive is powerful, suitable for all kinds of heavy solid wood cutting and engraving.

5. The tool change system adopts the international advanced technology, the hat-type automatic tool change system, which can intelligently exchange the required tools, and the tool magazine capacity can reach eight tools. The tool change time is only 8 seconds.

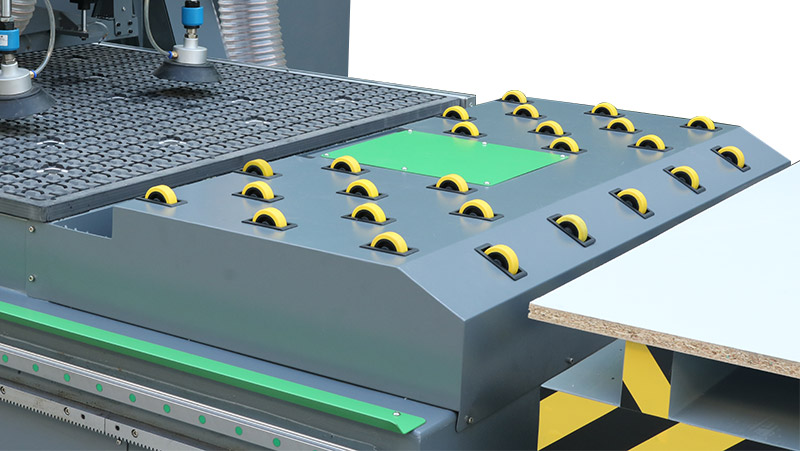

6. Automatic loading and unloading processing center six-zone vacuum adsorption table, which can effectively adsorb different size plates. The vacuum pump can choose the imported brand of oil-free vacuum pump to solve the problem of the water circulation vacuum pump in cold weather.

Equipment characteristics of automatic loading and unloading processing center

1. Comprehensive functions: This machine is a special engraving machine designed for cabinet and wardrobe manufacturers. It is designed for cutting, engraving, milling, slotting and perforating cabinets, wardrobes and other components. It has multiple functions, saving cost, time and labor.

2. Unique design: This machine is designed according to the principle of one machine for multiple purposes. It integrates pneumatic card loading and vacuum adsorption into one device, eliminating the burden of loading and loading cards for customers, saving customers labor costs and production time; its unique design can be processed Large, medium and small cabinets, wardrobes, time-saving, labor-saving, fast and accurate.

3. Special software for automatic loading and unloading machining center: easy to configure and operate, powerful CNC cutting software, which can automatically generate cutting lists, CNC processing bar codes, all hardware installation holes, and have automatic typesetting functions, dedicated to cabinets and wardrobes Manufacturer.

Application scope of automatic loading and unloading machining center:

1. Furniture industry: solid wood doors, composite doors, cabinet doors, interior doors, sofa legs, headboards, antique furniture and various panel furniture surface flower carvings and keyhole opening and other processes are completed at one time.

2. Decoration industry: carving processing of various decorative murals, screens, decorative patterns, three-dimensional wave panels, sound-absorbing panels, etc.

3. Automatic loading and unloading processing center industrial equipment accessories semi-finished products processing: deep processing of semi-finished products such as industrial sewing machine countertops and electrical countertops.

4. Musical instrument industry: piano head processing, guitar semi-finished products processing, surface carving of various musical instrument decorative patterns and three-dimensional curved surface production.

5. Mold industry: precision production of molds such as wood casting molds, lost foam casting foams, food molds (such as moon cake molds)

6. Handicraft industry: carving production of craft reliefs, shadow carvings, craft pendants, car accessories and other crafts.

7. Building model production

8. Advertising industry: Acrylic cutting and engraving, acrylic blister model making, engraving and making of badges and various signs.

The automatic loading and unloading machining center is a machine that mainly saves labor and increases the processing speed. The automatic loading and unloading machining center perfectly combines automatic loading, optimized cutting, punching, slotting, and automatic blanking in one process. Uninterrupted, to maximize efficiency and output, which can effectively reduce manual staffing, work intensity, increase production efficiency, reduce production costs, and improve product standardization; BCAM has more than 20 years of machine tool production history and is a global manufacturing One of the outstanding companies in the technical field. For more information, please consult BCAM manufacturers.

- Previous : The methods you need to master when using a stone CNC router

- Next : how to choose a stone cnc router

EN

EN Ru

Ru