- Your are here:

- NEWS

CNC router stepper motor selection guide

Upload to:01-22 2021

Upload to:01-22 2021

As a newbie to cnc routers, it is normal not to know how to choose a stepper motor. Cnc router stepper motor selection guide may be helpful to you.

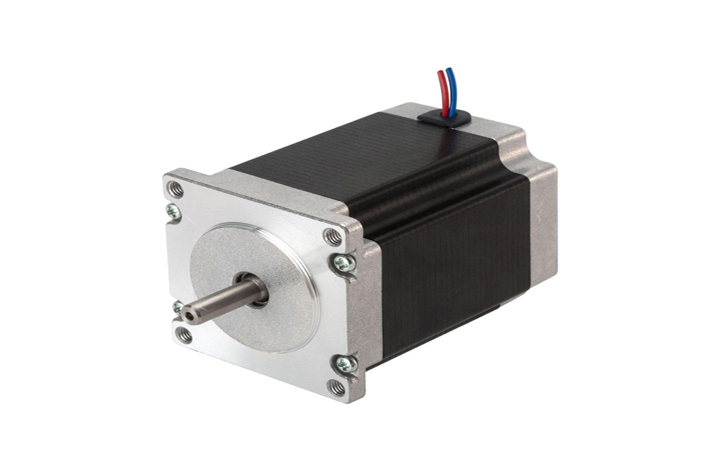

What is a stepper motor for cnc routers?

Stepper motors are DC motors with discrete motion. They have multiple coils organized in groups called "phases". By energizing each phase in turn, the motor will rotate one step at a time. With computer-controlled stepping, you can achieve very precise positioning and/or speed control. This is why stepper motor technology is commonly used in many applications that require precise motion control. Therefore, stepper motors are used in CNC milling machines due to precisely repeated steps and very consistent operating speeds.

How to choose cnc router stepper motor?

1. What is the holding torque? Holding torque is also called static torque, which refers to the torque at which the stator locks the rotor when the stepper motor is energized but not rotating. Since the torque of the stepper motor is close to the holding torque when running at low speed, and the torque of the stepping motor decays rapidly with the increase of speed, the output power also changes with the increase of speed, so the holding torque is a measure of step One of the most important parameters of motor load capacity. For example, if a stepper motor of 1N.m is generally mentioned without explanation, it can be understood that the holding torque is 1N.m.

2. What is the number of phases? The two-phase stepping motor has low cost, with a step angle of at least 1.8 degrees, large vibration at low speed, and fast torque drop at high speed. It is suitable for high-speed occasions with low requirements for accuracy and stability; three-phase stepping motor step distance The angle is at least 1.2 degrees, the vibration is smaller than the two-phase stepper motor, the low-speed performance is better than the two-phase stepper motor, the maximum speed is 30 to 50% higher than the two-phase stepper motor, suitable for high speed and the accuracy and stability requirements Higher occasions; 5-phase stepping motor has a smaller step angle, and its low-speed performance is better than 3-phase stepping motor, but the cost is higher. It is suitable for occasions with medium and low speeds and higher accuracy and stability requirements.

3. The principle of selecting the motor first and then the driver should be followed, and the load characteristics should be clarified first, and then by comparing the static torque and torque-frequency curves of different types of stepping motors, find the stepping motor that best matches the load characteristics; when the accuracy is high, should Use a mechanical deceleration device to make the motor work at the highest efficiency and lowest noise; avoid making the motor work in the vibration zone, if necessary, change the voltage, current or increase the damping method to solve the problem;

In terms of power supply voltage, it is recommended that 57 motors use DC 24V-36V, 86 motors use DC 46V, 110 motors use higher than DC 80V; large moment of inertia load should choose a larger frame size motor; large inertia load, high working speed , The motor should use a gradual increase in frequency and speed to prevent the motor from losing step, reduce noise, and improve the positioning accuracy when stopping; in view of the stepping motor torque is generally below 40Nm, beyond this torque range, and the operating speed is greater than 1000RPM, that is You should consider choosing a servo motor. Generally, AC servo motors can run normally at 3000RPM, and DC servo motors can run normally at 10000RPM.

4. When selecting the driver and the number of subdivisions, it is best not to choose the full-step state, because the vibration is greater in the full-step state; try to choose a driver with a small current, a large inductance, and a low voltage; use a driver larger than the operating current, and when low vibration or low vibration is required Use a subdivision drive for high precision, and a high-voltage drive for a high-torque motor to obtain good high-speed performance; when the actual motor speed is usually high and the accuracy and stability requirements are not high, it is not necessary Choose a high subdivision drive to save costs; under the condition that the actual motor speed is usually very low, a larger subdivision should be selected to ensure smooth operation and reduce vibration and noise; in short, when choosing a subdivision, The actual operating speed, load torque range, reducer setting, accuracy requirements, vibration and noise requirements of the motor should be considered comprehensively.

To choose a cnc router, you need to know more technical parameters. I believe that you understand the above selection points and have a more substantial understanding of the selection of cnc router stepper motors. For more technical parameters, you can also find BCAMCNC technicians with many years of experience in the cnc router industry .

- Previous : Cnc Wood Router Control system selection strategy

- Next : CNC Router for interior hollowing of FAW-Volkswagen

EN

EN Ru

Ru