- Your are here:

- NEWS

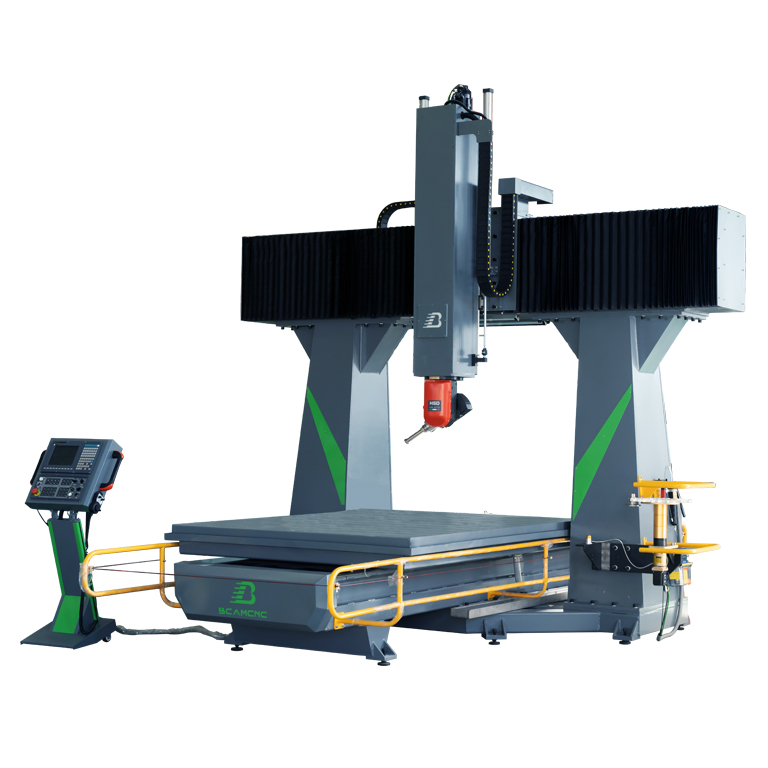

Main Functions of 5 Axis CNC Router Machine

Upload to:06-28 2024

Upload to:06-28 2024

As an outstanding representative of modern CNC machine tools, the 5 Axis CNC Router Machine has been widely used in many industries due to its performance in high precision, high efficiency and high flexibility. This article will take an in-depth look at the main features of a 5-axis CNC router machine and compare its benefits with a three- or four-axis engraving machine.

A 5-axis CNC router machine is a CNC machine tool that can engrave in five directions on the workpiece simultaneously. Its basic processing is carried out on Better Fit's three-axis coordinate system and closer to the workpiece surface for engraving and cutting materials. The main functions of the 5 axis CNC router machine include:

1.Processing complex curved surface parts: When the 5-axis CNC router machine processes complex curved surface parts, its unique five-axis linkage function can maintain the optimal cutting angle between the tool and the workpiece, achieving thus high precision and high efficiency processing.

2.Three-dimensional sculpture engraving: The high precision and flexibility of the 5-axis CNC router machine enable it to easily meet the needs of engraving various three-dimensional sculptures. Whether it is a large sculpture or a small precision sculpture, it can achieve precise engraving effects.

3.Multi-sided processing: The 5-axis CNC router machine can process multiple sides of the workpiece at the same time, greatly improving processing efficiency.

Advantages Comparison of 5 Axis CNC Router Machines

1.Processing Accuracy: The 5-axis CNC router machine can maintain the optimal cutting angle between tool and workpiece through five-axis linkage, achieving higher processing precision. In contrast, when a three- or four-axis engraving machine processes complex curved parts, due to the angle limit between the tool and the workpiece, its processing precision is often difficult to reach the level of a 5 axis CNC router machine.

2.Processing efficiency: The 5-axis CNC router machine can process multiple surfaces of the workpiece at the same time, and there is no need to frequently change tools and parts during processing, saving a lot of money tool change and machine adjustment time, and improve processing efficiency. When three- or four-axis engraving machines process multi-faceted parts, they need to frequently replace tools and parts, and the processing efficiency is relatively low.

3.Processing scope: 5-axis CNC router machines are suitable for processing various complex curved surface parts and engraving three-dimensional sculptures, while three or four-axis engraving machines have a relatively limited processing range. 5 axis CNC router machine can meet more diverse and difficult processing needs.

4.Flexibility: The 5-axis CNC router machine can flexibly adjust the angle and position of the tool during processing to adapt to parts of different shapes and sizes. However, it is relatively difficult to adjust the tool angle and position on a three- or four-axis engraving machine.

- Previous : What is the function of frequency conversion CNC cutting machine?

- Next : 5-Axis CNC Router Application

EN

EN Ru

Ru