- Your are here:

- NEWS

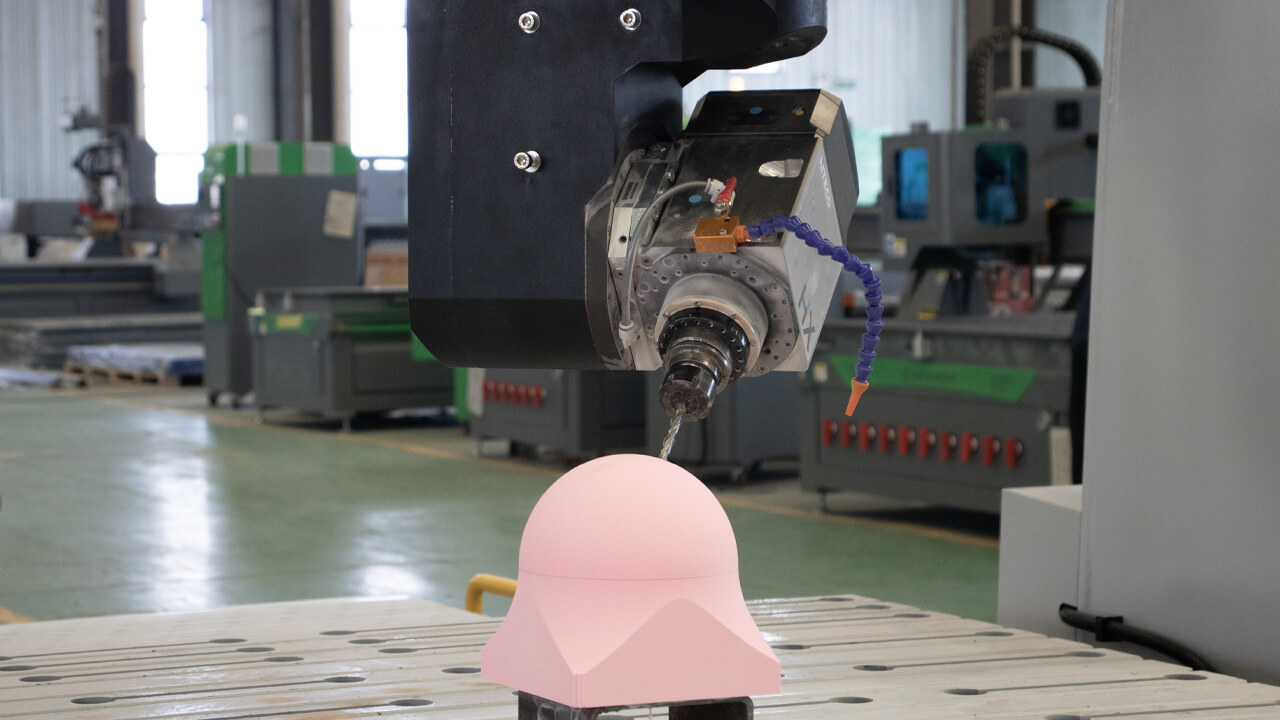

5-Axis CNC Router Application

Upload to:03-31 2025

Upload to:03-31 2025

5-Axis CNC Router: The Ultimate Solution for Wooden Furniture, Foam Molds, Aluminum Molds, and Composites

In today’s competitive manufacturing landscape, precision, efficiency, and versatility are paramount. A 5-axis CNC router stands out as a game-changing tool, capable of handling complex geometries across diverse materials like solid wood, foam, aluminum, and composites. This article explores its transformative applications in these industries, highlighting key benefits and real-world use cases.

1. Unmatched Precision for Solid Wood Furniture

A 5-axis CNC router revolutionizes custom wooden furniture production by enabling:

● Complex 3D Carvings: Create intricate designs (e.g., curved legs, ornate panels) in a single setup.

● Reduced Waste: Optimize material usage with advanced nesting software.

● Time Savings: Eliminate manual repositioning for multi-angle cuts.

Example Applications: High-end cabinetry, artistic sculptures, and ergonomic furniture.

2. Rapid Prototyping & Foam Mold Fabrication

For foam molds (used in aerospace, automotive, or packaging), 5-axis machining offers:

● Smooth Surface Finishes: Ideal for molds requiring minimal post-processing.

● High-Speed Cutting: Efficiently shape low-density foam with minimal tool wear.

● Complex Cavities: Machine undercuts and internal features effortlessly.

Ideal for: Sculptural prototypes, insulation components, and lost-foam casting patterns

3. Durable Aluminum Molds with Superior Accuracy

Aluminum molds demand rigidity and detail—key strengths of 5-axis CNC:

● Hard-Milling Capability: Directly machine hardened aluminum (e.g., 6061-T6) for injection molds.

● Extended Tool Life: Continuous tool engagement reduces wear vs. 3-axis machines.

● Micro-Detail Replication: Perfect for aerospace or automotive mold inserts.

Applications: Die-casting molds, blow molds, and precision tooling.

4. Advanced Composite Material Processing

From carbon fiber to fiberglass, composites require specialized handling:

● Delamination Prevention: Adaptive toolpaths minimize fraying or layer separation.

● Contoured Trimming: Accurately cut curved composite parts (e.g., drone frames, UAV components).

● Multi-Material Compatibility: Switch between laminates and core materials seamlessly.

Why Choose a 5-Axis CNC Router?

● Versatility: One machine for diverse materials and industries.

● Cost Efficiency: Lower labor costs and faster turnaround vs. manual methods.

● Future-Proofing: Adapt to evolving design trends (e.g., lightweighting in aerospace).

Conclusion

Whether crafting heirloom furniture, prototyping next-gen foam molds, or producing high-tolerance aluminum tools, a 5-axis CNC router delivers unmatched flexibility and precision. Invest in this technology to elevate your production capabilities and stay ahead in 2025’s dynamic market.

Contact us today to explore the right 5-axis solution for your needs!

E-mail:admin@bcamcnc.com

WhatsApp: 8615154109683

Note: This article can be tailored further with customer testimonials or technical specifications upon request.

EN

EN Ru

Ru