- Your are here:

- Home >

- Vacuum laminating machine

Models : BCV1330

Application :Woodworking Process

Leadtime : 10 working days

Certificate : CE,ISO

Voltage :220v/380v

Customized :YES

Warranty : 3 years

Supply Ability : 50 Sets/Month

Oversea Warehouse&Office : Dubai,Wittingen Germany, Birmingham UK

- Advantage

- Details

- Specifications

- Videos

- Foot print

- Download

| ▄ The surface of the covered object is evenly covered, has good fit, and can effectively protect the stability of the shape of the object, improve product quality, and extend the service life of the product; it is also environmentally friendly and uses low energy consumption. |

|

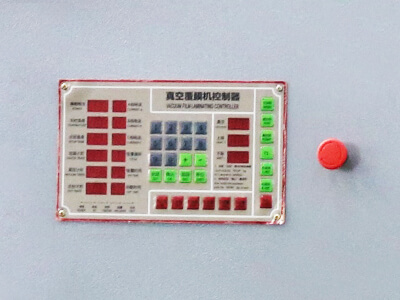

| 1:The equipment adopts 7-inch touch screen and plc control, friendly interface, intuitive and easy to operate, with memory function, can store a variety of process data, and improve work efficiency. |

2:The machine adopts high stress steel structure, ensure the equipment running smoothly, transport more at ease. High sealing ,as to improve the processing efficiency of equipment. |  |  |

|

| 3:With alarm system.after heating reached,it alram to remind for next step or accidence happen, we can stop in time and the light inside can be visible for see the PVC film or veneer changing. |

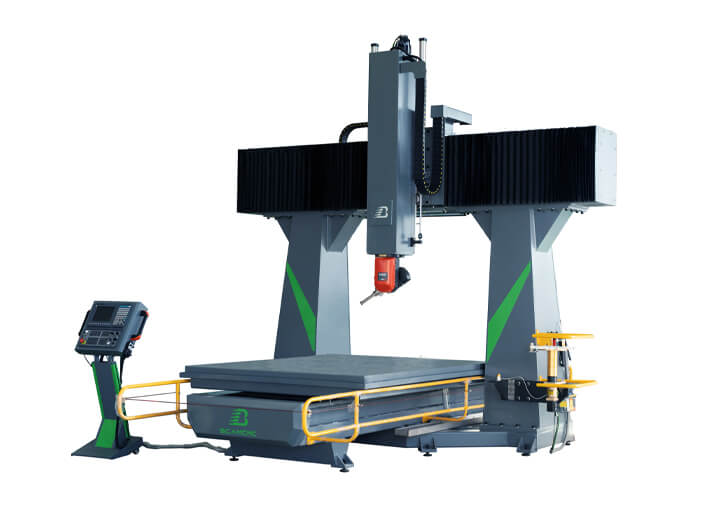

BCV1330 Vacuum laminating machine

| ● Working area: 1300×3000 |

|---|

| ● CE standard |

| ● Panel Loading and Unloading system (Automatic ) |

| ● Japan Yaskawa Servo Motor |

| ● 15mm Heavy duty body |

| ● Active protection safety system |

| ● Ucancam / ArtCam/TYPE3/ VCarve/VCarve Pro |

| ● 25mm Heavy-duty Hiwin HG Series linear bearing |

| ● Vacuum table+T-solt |

| ● Taiwan Syntec Control system (4 Axis) |

| ● Japan Yaskawa servo motor and drivers system |

| ● Delta brand VFD-B variable frenquency drive |

| ● Taiwan Syntec Control System |

| ● Tool Cone Holder-for east bit changing |

| ● Solid State limit switches |

| ● Airtech pro Dust-free extraction hood |

| ● 3 Years Warranty |

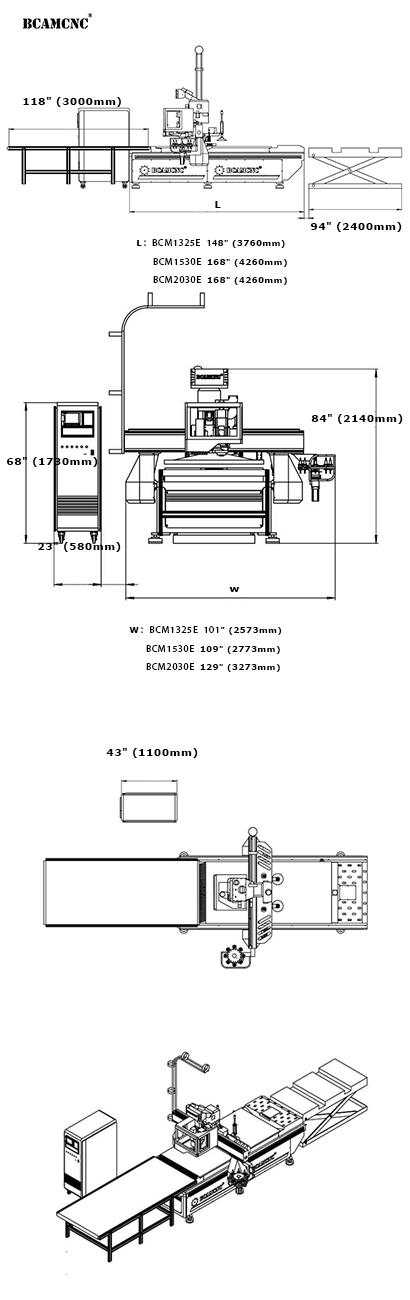

| Parameters | Vacuum laminating machine BCV1330 | |

|---|---|---|

| Positioning Accuracy (mm) | 0.03mm | |

| No. of Spindles | ATC | |

| Working Table Size(mm) | 2000×4000 | |

| Travel (X Axis)(mm) | 2000mm | |

| Travel (Y Axis)(mm) | 4000mm | |

| Repeatability (X/Y/Z) (mm) | 0.03mm | |

| Spindle Motor Power(kW) | 9kw | |

| Voltage | 380V | |

| Dimension(L*W*H) | 2100*4000*200MM | |

| Weight (KG) | 2250 |

| What materials can a CNC Router process?

A BCAM CNC router can machine a lot of different materials. Here listed just a few materials that can be machined 2D or 3D: ►Soft metals / Non-ferrous metals ►Brass ►Aluminium ►Titanium ►Noble metals such as silver, gold ►Wood ►Multiplex ►Plastics ►Acrylic glass ►Granite and marble Is important to note that some materials like Aluminum, require cooling during the actual milling operation. The heat generation means that chips can clog or glue the flutes of the milling machine and the milling tool breaks. Suitable coolants and lubricants can be found in the range of most CNC milling machine manufacturers. What criteria are decisive when buying a BCAM CNC Router? If you have decided to buy a BCAM CNC Mill to facilitate some work or to make special work possible, immediately one question comes to mind: “What do I have to consider when buying a CNC Router?” ►The size Before I search for a suitable manufacturer, I should have a good idea of in which size I want to edit the desired material. Because the maximum traveldictates the maximum size of my workpiece. Do I perhaps prefer to process larger workpieces? Then I should observe the maximum travel of the selected machine. ►The motor and its performance Furthermore is crucial which materials I would like to process because this depends on the required performance of the milling spindle. Soft materials such as wood consume significantly less drive power than hard metals such as steel or cast steel. Here a competent milling machine manufacturers will be happy to advise you. ►Hardness and toughness of the material Also concerning the torsional rigidity of the machine, the material to be processed is crucial. Soft materials will demand the milling machine other than hard materials, such as aluminium and steel. The harder a material is, the stiffer the CNC Router should be built. Only in this way a high accuracy in hard materials, especially metals, are guaranteed. ►Precision A CNC Router Machine should be as well adapted to the material to be machined as possible. Someone who workes mainly wood should get a one-on tailored CNC machine. The more accurately the machine fits the demands of the material, the more accurate the milling results. With these four questions I quickly find out which CNC Router is suitable for my needs: 1.What size are my workpieces to be processed? 2.What engine power do I need for my hard / soft material? 3.How hard are the materials to be processed concerning the required torsional stiffness of the machine? 4.How exactly is the selected CNC Router adapted to my desired materials / workpieces? |  |

|---|

- File Name Type Download

Find out More Products

Tel:0086-15154109683

Tel:0086-15154109683

Fax:0086-15154109683

Fax:0086-15154109683

Mobile:+86 15154109683

Mobile:+86 15154109683

Skype:

Skype:

E-mail:admin@bcamcnc.com

E-mail:admin@bcamcnc.com