- Your are here:

- Home >

- BCAM OptiNest with BCM1325

BCAM OptiNest with BCM1325

Upload to:08-30 2019

Upload to:08-30 2019

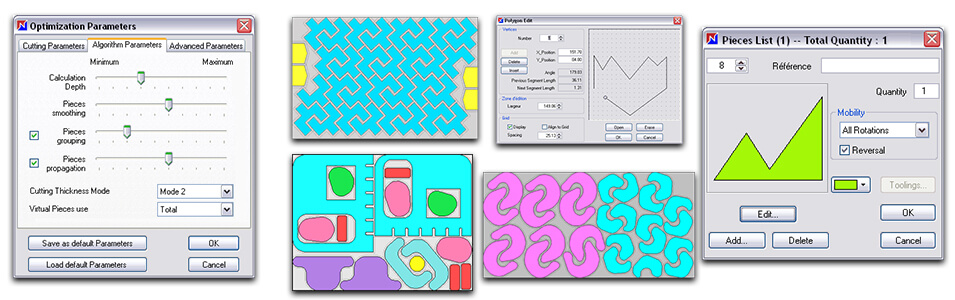

● BCAM OptiNest

Professional nesting software for highly optimised cutting of parts of any shape on to sheets of any shape

The best quality, price and performance mix on the market

● OptiNest's Some Key Features

● OptiNest's Advantage...

√ Minimise material waste with true shape nesting

√ Fully manufactured parts directly on your CNC machine

√ Supports bored and tooled pieces and all polyline shapes

√ Seamlessly integrates with all versions of Polyboard

√ Optimise according to your own priorities

√ OptiNest accommodates 4 rotation levels and flipping

√ Parts can be drawn with any shape and cut out

√ Parts can be imported from DXF files or drawn directly in Optinest's graphic editor

√ OptiNest can manage bored pieces

Speak to one of our specialist sales representatives who will help you prepare a personalized machine specification. Our sales reps have many years of technical experience to help guide you through the necessary steps to selecting the ideal CNC Router for your unique needs now and in the future.

EN

EN Ru

Ru