- Your are here:

- Home >

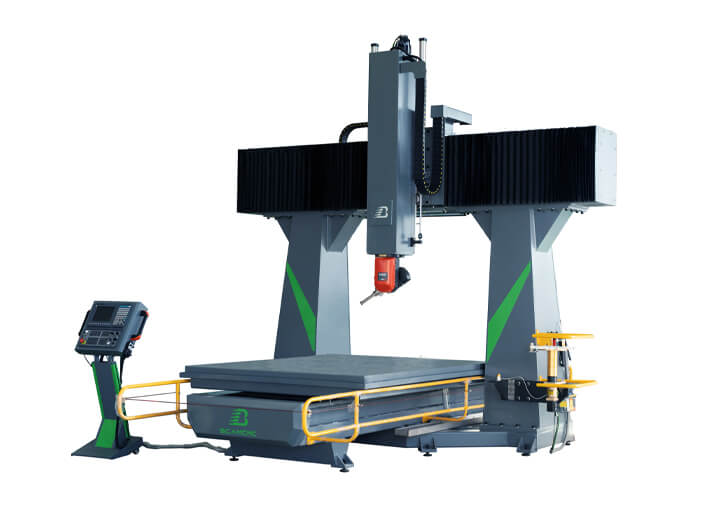

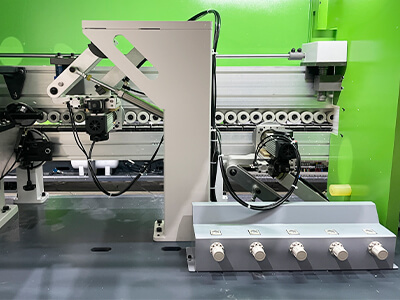

- 8 function edge banding machine

Models : BCF450DJ

Application :Panel Furniture, Woodworking

Leadtime : 8-12days

Certificate : CE, ISO

Voltage :380V/3P/50HZ,220V/1P/50HZ

Customized :Size can be customized

Warranty : 2 years

Supply Ability : 50 Sets/Month

Oversea Warehouse&Office : Dubai,Wittingen Germany, Birmingham UK

- Advantage

- Details

- Specifications

- Videos

- Foot print

- Download

| AUTOMATIC SINGLE-SIDED EDGEBANDING MACHINES |

|---|

| 1. LOW INVESTMENT, LONG TERM RELIABILIT |

2. BUILT ACCORDING TO THE SPECIFIC PRODUCTION REQUIREMENTS 3.PERFECT FINISHES WITH EVERY TYPE OF PROCESS AND TOP QUALITY FINISHED |

| 4GROUND-BREAKING TECHNOLOGY, FOR TOP PERFORMANCE |

|

| 1:Automatic edge banding machine accessories. Rubber roller. Rubber block. Calculator. Frequency conversion. |

2:The automatic edge banding machine can also scrape away the corrugated traces. |  |  |

|

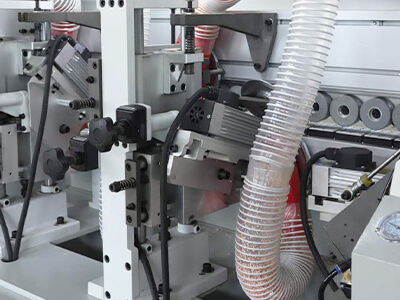

| 3:The CNC control panel controls the operation of the fuselage.touch screen design.The operation is fast and labor-saving. |

3:The CNC control panel controls the operation of the fuselage.touch screen design.The operation is fast and labor-saving. |  |  |

|

| 5:Glue pot fast sol system, the shortest only 15 minutes, efficient glue change, can quickly change the glue box. Ensure the sealing glue clean without yellowing. |

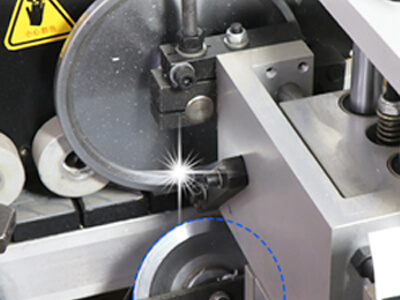

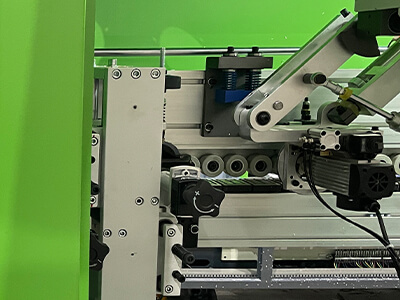

6:Through the structure of automatic tracking by mold and high frequency high speed motor, the cutting surface is smooth and smooth. And with the protection of the head collision plate, strengthen the stability of the head. |  |  |

|

| 7:Rough trimming tool is a flat knife, used to repair the processing of the upper and lower parts of the plate edge sealing tape excess sealing material, the use of high frequency high speed motor to achieve rapid cutting. |

8:The finishing knife is R2 oblique trimming knife, leaving 5~6 wire margin for scraping, using mold automatic tracking and high frequency motor to achieve fast cutting, R2 oblique trimming knife trim radian. |

|  |

|

| 9:Can be rounded up and down, as well as the four corners of the garden, so that the end face of the plate is more smooth and beautiful. |

10:It is used to eliminate the wave marks caused by the cutting process of non-linear trimming, so that the upper and lower parts of the plate are more smooth and neat. At the same time, the scraping can also adjust the size of the arc, so that the edge effect is better. |

|  |

|

| 11:Clean the processed plate with cotton polishing wheel, remove the excess glue stains, and make the edge section more smooth and tidy through polishing. |

BCF450DJ Egde Banding machine

| ● Overall Size: 4500*1000*1600mm |

|---|

| ● CE standard |

| ● Panel Height 10-60mm 0.39-2.36inch |

| ● Thickness of Edge banding Materaialin rolls/Strips 0.4-3/8mm 0.55-2.51inch |

| ● Panel Protrusion from Track 25mm 0.95inch |

| ● Min Panel Lenth 150mm 5.9inch |

| ● Min Panel Width (With length 150mm ) 85mm 3.34inch |

| ● Min panel width (with length 250mm ) 50mm 1.96inch |

| ● CNC PC Control system |

| ● Track Feed speed 12m/mins 39.37ft/mins |

| ● Pneumatic connection 7 Bar |

| ● Glue Pot capacity ( Approx ) 2kg |

| ● Glue pot Heating tine at 1/2 load ( approx ) 20 minutes |

| ● With Pre-milling Unit 8kw |

| ● With Pre-milling&Corner rounding unit 10kw |

| ● Machine Total power 16kw ( 380v/50hz/3p ) |

| Parameters | BCF450DJ | |

|---|---|---|

| Edge thinkness | 0.4-3mm | |

| Feed speed | 12-20m/min | |

| Panel thickness | 10-60mm | |

| Panel Length | >=150mm | |

| Panel width | >=60mm | |

| End cutting motor | 0.55kw*2@18000rpm | |

| Rough trimming motor | 0.75kw*2@18000rpm | |

| Fine trimming motor | 0.75kw*2@18000rpm | |

| Buffing motor | 0.18kw*2@18000rpm | |

| Total motor power | 16kw | |

| Max. Rapid Travel Rate | 30m/min | |

| Max. Working Speed | 20m/min | |

| Working Pressure | 0.8Mpa | |

| Netweight | 2700kg |

| What materials can a CNC Router process? THE MARKET DEMANDS a change in manufacturing processes that enables companies to accept the largest possible number of orders. This is coupled with the need to maintain high quality standards whilst offering product customisation with quick and defined delivery times, as well as responding to the needs of highly creative designers. LOW INVESTMENT, LONG TERM RELIABILITY BCAM RESPONDS with technological solutions that highlight and support technical expertise as well as process and material knowledge. BCF506 is a range of automatic single-sided edgebanding machines purposely created for craftsmen and companies looking for user-friendly, customised production and flexible solutions in a limited space. |  |

|---|

- File Name Type Download

Find out More Products

Tel:0086-15154109683

Tel:0086-15154109683

Fax:0086-15154109683

Fax:0086-15154109683

Mobile:+86 15154109683

Mobile:+86 15154109683

Skype:

Skype:

E-mail:admin@bcamcnc.com

E-mail:admin@bcamcnc.com