- Your are here:

- NEWS

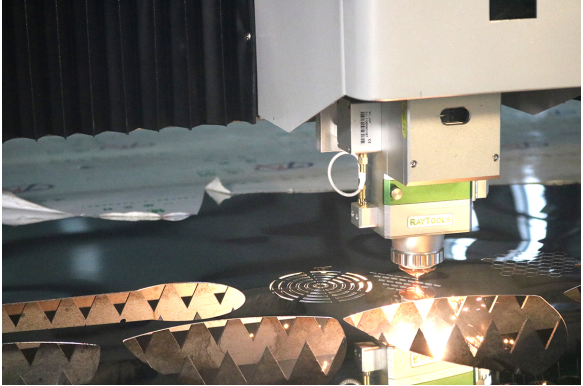

How to debug the accuracy of fiber laser cutting machine

Upload to:08-12 2021

Upload to:08-12 2021

1. When the spot of the focus laser is adjusted to the minimum, perform spot shooting to establish the initial effect. The focal position is judged by the size of the spot effect. As long as we look for the minimum spot of the laser, then this position is the best Processing the focal length, and then start the processing work.

2. In the first part of the debugging of the laser cutting machine, we can use some debugging paper and workpiece waste to spot the accuracy of the focal position. Move the position of the height of the upper and lower laser heads, and the laser spot size will have different size changes when the spot is fired. Make adjustments to different positions several times to find the smallest spot position to determine the focal length and the best position of the laser head.

3. After the fiber laser cutting machine is installed, a scribing device will be installed on the cutting nozzle of the CNC cutting machine, and a simulated cutting pattern will be drawn through the scribing device. The simulated pattern is a 1m square. A circle with a diameter of 1m is built in, and the four corners are drawn diagonally. After drawing, use a measuring tool to measure whether the drawn circle is tangent to the four sides of the square. Whether the diagonal length of the square is √2, the central axis of the circle should bisect the sides of the square, and the distance between the intersection of the central axis and the two sides of the square and the intersection of the two sides of the square should be 0.5m. Test the distance between the diagonal and the intersection point to determine the cutting accuracy of the equipment.

The above is the experience we have summed up in the actual cutting process of the fiber laser cutting machine. The operator can carry out the practical operation according to the above method and verify it. For more relevant knowledge, you can continue to pay attention to us: https://www.bcamcnc.com, we will continue to update for you.

- Previous : What are the application scope of engraving machine

- Next : Introduction to the types and functions of CNC stone engraving machines

EN

EN Ru

Ru