- Your are here:

- NEWS

How To make Quality CNC Router?

Upload to:06-30 2021

Upload to:06-30 2021

This article is definitely worth reading on before purchase of CNC Router Machine.

CNC Router Machine is characterized by a high complexity of the design, which includes a lot of components, on technical health, quality of performance and correctness of work which depend on the comfort of operation and performance of the equipment as a whole.

THE MAIN ELEMENTS OF BCAM CNC Router Machine DESIGN

Here's a look at the most significant components that affect the quality of equipment:

1.Paint coating. Paint based on alcid-phenol varnish, containing a large number of special targeted additives: anti-corrosion fillers, persistent pigments and organic solvents, is used to stain the metal parts of the machine. Such paint materials are intended for painting industrial equipment. The finished coating is highly resistant to chipping, scratches and other mechanical damage, effectively protects the metal parts from rusting and retains a neat appearance for a long time even when the machine is actively used.

2.Machine Vibroses. When engraving and 3D milling small products at high speeds and accelerations, the machine's drive mechanisms experience high loads associated with frequent and sharp braking and acceleration of moving parts. Reducing the load allows the installation of the machine on the vibrator, which provide the necessary micro-mobility of the mill, making compensatory movements in the opposite of the portal jerks and carriages. At the same time, the drive nodes are unloaded, which allows you to work at a higher speed and with greater performance, excluding vibration and resonance.

3.Table material. To make the working surface of the table in production is introduced viniplast - a material made from primary raw materials. Its main advantage is a clean chemical composition, which provides high rigidity and homogeneity of the sheet without inlays, abrasive particles and other debris, characteristic of products made of recycled material. The fres used to align the machine's work surface always remains sharp. Frasering takes place qualitatively, without excessive pressure, and, accordingly, without bending the material of the table between the cells of the mill during processing. Once aligned, the surface of the table remains "in the horizon" and does not compensate for the deflection gained from the tool's push during processing.

4.Vacuum system. A high-quality pipeline manufactured by Chinese best vacuum pipeline suppliers is used to assemble the vacuum system. The company specializes in the production of pipeline products for a wide range of industrial packaging, irrigation and overflow equipment. This supplier was chosen by us because these pipelines do not shrink and exclude the formation of micro fractures during long-term operation. All compounds are assembled on a specialized sealant and controlled by metal clamps. A large section of the vacuum dispenser with ball taps aligns the force of the vacuum press on the entire desktop plane. Due to all of the above, the vacuum system has been operating flawlessly for many years.

5.Frame of Mchine. CNC Router Machine frame is made of massive metal beams located on the perimeter of the table and in places where guides and jagged reeks are installed. In the enhanced version, the internal "grid" of the frame, supporting the surfaces of the desktop, is also made. This ensures an accurate table horizon for any load.

6.Protecting the guides. To protect the guides on the frame, there are protective visors made of three-millimeter steel sheet. They protect guides and jagged slats from sprinkling milling products on them and do not deform from impact or touch when stacked on the desktop heavy materials.

7.The Gantry supports. In the construction of the supports of gantry, the place of installation of linear bearings is as marked as possible. The upper platforms of the supports are expanded, equipped with amplifiers and after installation on powerful bolt connections make a single whole with gantry. The increased support base of the line bearings, combined with a rigid connection of supports and gantry, provides accurate and fast-speed operation of CNC Router Machine

8.The Gantry. The gantry beam is made of a massive steel profile with an amplifier located on the back of the portal. The amplifier acts as a "shelf" for the cable chain and is additionally a powerful design element that strengthens the gantry when the load is twisted or deflected. In the reinforced versions of the equipment, the section of the gantry beam is doubled to 280 x 180mm, and to give the necessary strength inside there is a double steel jumper. Also, the double section of the 150 x150 mm has a gantry amplifier.

9.The guides. The build uses high-precision guides and linear bearings HIWIN ,TBI,THK (Taiwan or Japan ). The delivery of these components to us is carried out by the official representative in CHINA . The choice of this supplier is made as part of the fight against counterfeit products of lower quality. In the practice of finding suppliers of components of equipment when applying for various productions there were cases when the manufacturer offered to label their products with the names of well-known brands, precisely copying the appearance of the product, but, alas, not its quality.

High-quality Linear guides are one of the most important design elements of the machine, responsible for accuracy and speed of processing.

10.Specialized fastener. For the qualitative assembly of the machine nodes, and, especially, in the installation of guide and jagged reeks, a specialized fastener of the strength class 8.8; 10.8 and 12.8 produced by Russia or Finland, made of high-strength steel with subsequent hardening, is used. When exposed to high load, such fasteners are not "stretched", not deformed, the connection always remains reliable. Anaerobic Loctite threading fixtures are used to prevent the joints from weakening due to micro-vibrations. The composition completely fills the space in the threaded connection, turning when exposed to metal into a rigid plastic.

11.Cable chains . BCAM CNC Router Machine is fitted with high-section cable chains made of high-quality plastic, which does not dry out and does not become brittle after long operation. Each element of the chain is characterized by high strength and ensures the correct operation of the moving cable connections of the machine. The enlarged section of the cable chains makes it possible to put electrical conductors in them freely in order to prevent the erasure and formation of the halls. When the equipment works in the closed type of cable chains accumulate products milling materials, which leads to the eraser of insulation and failure not only of the electric conductors, but also electronic systems of the machine due to closure. The open-type cable chains we use exclude the accumulation of milling products in them and allow us to assess the condition of mobile electrical connections at any time.

12.Mobile cable connections. Reliability of equipment with mobile elements, such as a gantry and carriage, even with the use of the highest quality components will be low, if not paid due attention to the quality of the connective cable. In the production of BCAM equipment, the cable some of products of the German companies ,LFLEX® (LAPP GROUP) and Nexans specialized series are used for use in mobile connections. This type of cable is designed for many years of uninterrupted operation in the design of cranes, high-speed elevators, industrial robots, automated production lines.

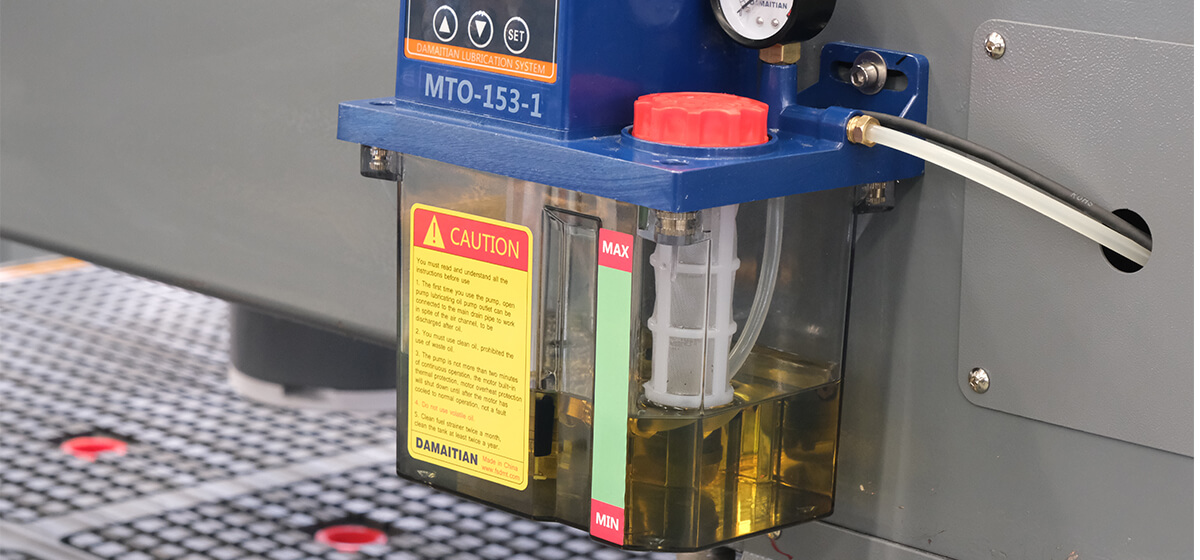

13.The bearing grease system. The piping system provides a lubricant to all linear bearings and SVP nuts on the axis of the J. To perform daily maintenance of the machine, it is enough to press the pump lever on the tank with oil. The ease of service contributes to the regular maintenance of the equipment, and accordingly its durability. To prevent oil from falling from the carriage on the processed product, a tray is provided for its collection. Since the machine requires a minimum amount of oil, the draining of the receiving tray should be done no more than once every ten days. The procedure is carried out with the help of absorbent textile materials.

14.Electrical wiring, launchers and protective elements. The assembly of equipment pays special attention to electrical connections. There are about a thousand such connections in the machine, and each element must be reliable. The WIRing of THE BCAM CNC Router Machine is switched by high-quality screw terminals Phoenix Contact (Germany), which provide reliable connections, do not spoil from vibration and do not break the carving during installation. All conductors are supplied with 9ps.

The system's inclusion buttons, the central power supply switch, and the power supply contacters are purchased from Schneider Electric

manufacturers. Attempts to use cheaper components have led to equipment malfunctions due to their short-livedness, unreliable contacts, substandard threading nodes, weakening of connections due to concussions in the transport of equipment and from micro-vibrations during operation. All savings were negatively affected in the form of a load on service, simple equipment from customers, and, therefore, a negative impact on their business. At the moment, the electrical components used are purchased only from officials, guaranteeing the authenticity of the manufacturer and the quality of the products.

15.Protect the wiring. Electrical communications connecting the control cabinet and the machine need high-quality protection from mechanical damage, as they are on the floor of the production room. Often you can see the following picture: the wires connecting the cupboard and the machine, protected by a corrugated sleeve, and everything seems to be fine, but in the place of entering the corrugated in the machine or cupboard the last falls out of the sledgehams, and the wires in this place remain unprotected.

In the process of production of our machines, we pay attention to such small things and apply only high-quality protective components that are not spontaneously understood and reliably protect the machine.

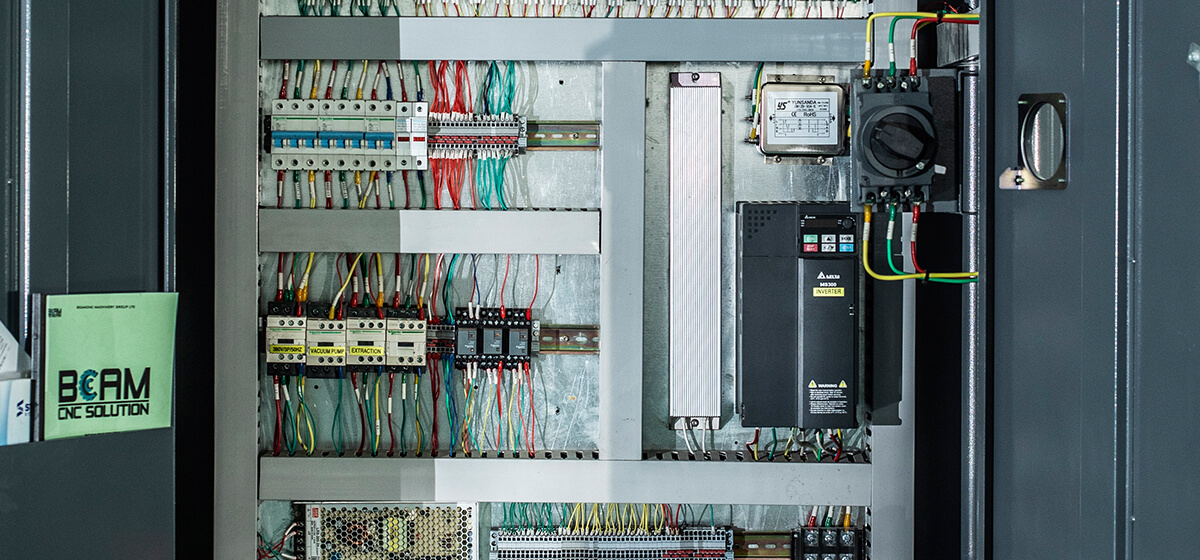

16.The layout of the control cabinet. The electronic part of the machine control consists of low-voltage and power equipment, high-frequency jamming sources and power lines. The correct location of all the items in the control cabinet ensures the stability of the equipment, eliminating the possibility of flooding and noise.

When installing control cabinets, we try to remove power and low-voltage elements from each other as much as possible. Thus, the frequency converter, which manages the spindle, is located in a separate compartment from the rest of the electronic equipment. High-voltage and low-voltage conductors are spread across different tires, and high-frequency or logical signals are transmitted through screened wires.

17.Belts and pulleys . .. Machines with belt gears are equipped with pulleys and drive belts from well-known manufacturers of mechanical in china . The choice of these suppliers was made after many attempts to equip equipment with more democratic pulleys and belts of other manufacturers. Their shortcomings were expressed in the inconsistency of the geometry of the tooth belt and pulley. With a strong bend of the belt around the small leading pulley, the hooking of the teeth occurred with palpable clicks. On a large led pulley, the teeth of the belt were loosely sly between the teeth of the pulley. Thus, for the normal operation of such a gearbox required an increased tension of the belt, and, therefore, an increased load on the bearings of the gearbox. All this caused noise, vibration and inaccurate machine operation.

The gearbox works smoothly and silently and does not require excessive belt tension for normal operation.

18.The shaft and the body of the belt gearbox. The parts of the belt gear are given special attention. The shafts of gearboxes, which are planted with jagged gear and led pulley, after turning processing are resurfaced and hardened. This treatment allows the product to be performed with a high precision qualite, providing a tight landing of bearings and impressive mechanical strength. The case of the gearbox is made using the same technology. The pulley is used to attach a veneer to the shaft. This node is the most responsible in the machine, and even a minimal backlash will lead not only to inaccurate operation of the equipment, but also to the complete failure of it due to the constant sign of the per operated load on the veneer connection. When assembling, we use a "hot" installation method, in which after cooling the knot tightly connects in tight - the veneer connection does not weaken, the machine works accurately and steadily.

19.Adjust the tension of the belt and press the gear to the rake. For convenient belt tension adjustment in the gearbox design, there is an adjustable screw that allows to lower or increase the tension, to make a fine adjustment. The same is done and adjusting the hooking gear with the jagged rake of the drive mechanisms of the machine. Proper adjustment of these nodes is important for the stable and accurate operation of the machine.

20.Planetary gearboxes. If you want to buy a machine on planetary gearboxes, you should pay attention to the manufacturer of this site. SHIMPO (Japan) gearboxes are used in our production. The Japanese quality of components is an axiom, proof of this is the lack of warranty cases for this part, and an isolated case of replacement of the gearbox occurred after several years of dense operation of the equipment.

21.The jagged transmissions are oblique. The main advantage of the oblique transmission is that the teeth are smoothly hooked and work at high speeds without significant noise and vibration. Most milling and engraving machines are equipped with scythe-toothed slats produced in China. Among the producers of reeks there are plants with very decent quality, and producing products suitable for the collection of conveyor, sorting, lifting mechanisms, but not high-precision coordinates.

For quite a long period, during which our company produces equipment, several suppliers have been checked and one with reference quality has been selected.

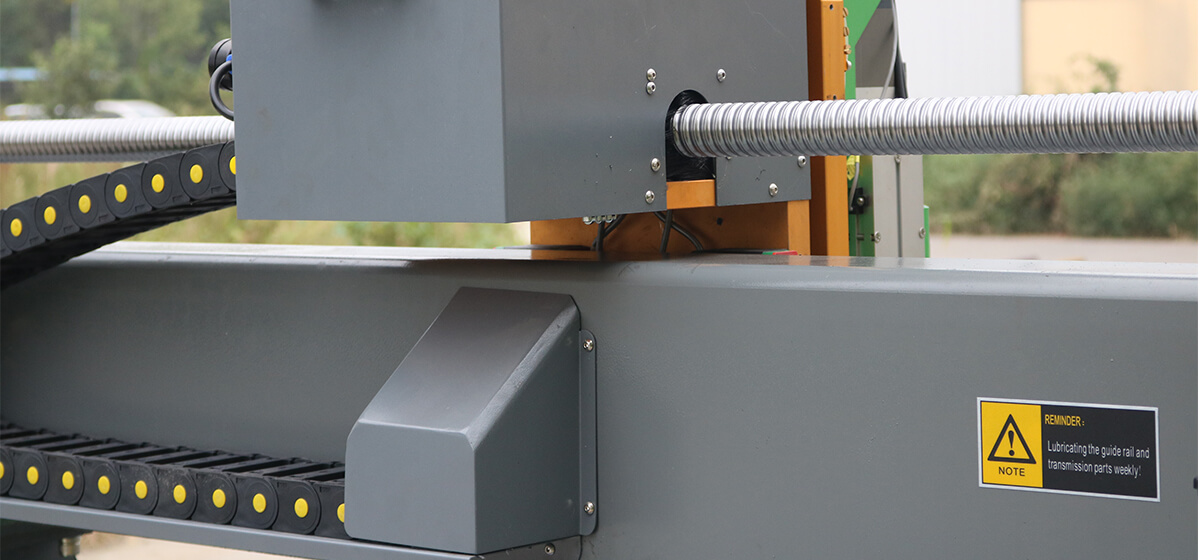

22.Ball-screw transmissions of the SVP and radial-resistant bearings. The ball-screw transmission of the vertical spindle movement is one of the most loaded pieces of equipment. In order for the machine to be truly reliable, the choice and installation of these components should be approached as carefully as possible. Thus, the use of components for "domestic" level machines or counterfeit parts is likely to lead to the appearance of crunch and further jamming of the node even with its regular maintenance. Our production uses TBI (Taiwan) SVP, supplied by the company's official representative. The SVP data works long and reliably, while maintaining the accuracy of the tool's positioning.

The second important element of the spindle moving along the vertical axis is the radially stubborn bearing, which takes on the weight of the

carriage. After careful selection, we settled on the bearings of NSK (JAPAN) and use them long ago without complaints and comments.

23.Spindel. Depending on the customer's needs, the machines are equipped with spindles of 1.5 kW to 18 kW. Liquid-cooled spindles are used for low-cost equipment models by the Chinese company CHANGSHENG. Please note that budget - does not mean bad - these spindles are made qualitatively and work reliably. The premium machines are equipped with HSD (Italy) spindles, which we purchase from the official representative of HSD in CHINA and some of Spindle from BENZ (Germany ) that can cut ,milling Aluminum ,brass and more soft-metal ..

HSD produces a wide range of products, and the line has wood-processing spindles and non-ferrous metal milling, air and liquid cooling, designed for manual or automatic tool

change. Thus, when the machine is equipped, you can choose a spindle, suitable for specific production tasks, so as not to overload it in the future and not to overpay for unnecessary characteristics.

24.Frequency converter. To control the stability of spindle revs, the machines are equipped with a DELTA frequency converter. This brand is synonymous with quality - in the history of production and maintenance of BCAM machines there have been almost no failures of this kit.

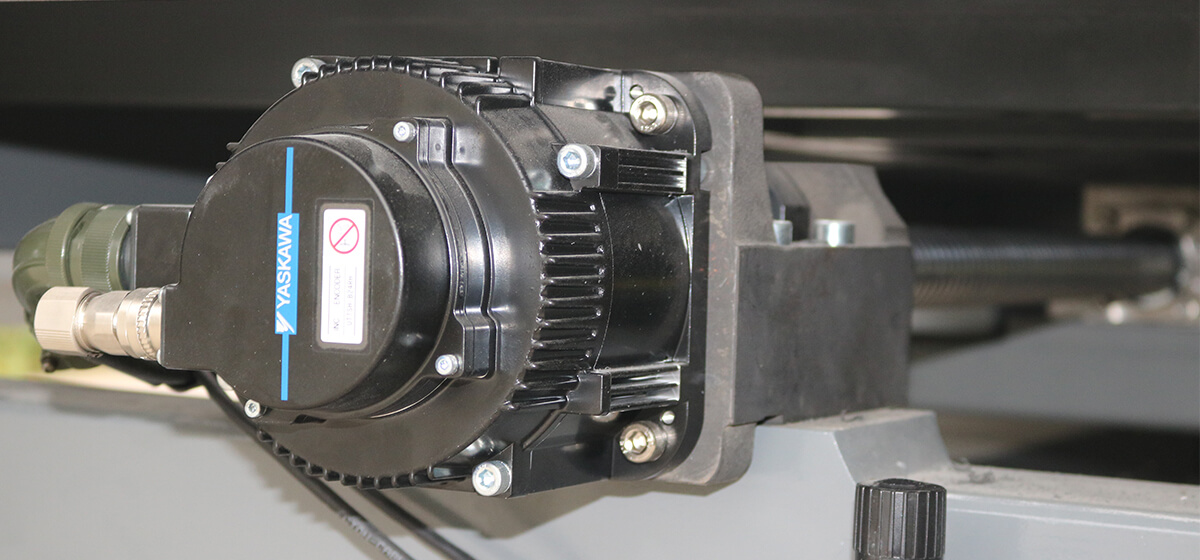

25.Japan YASKAWA servo. BCAM equipment is equipped with YASKAWA drives and controllers. YASKAWA is one of the world leaders in industrial automation and drive systems. Deliveries of YASKAWA components for the production of BCAM equipment are carried out by a Russian representative of the concern.

THE BCAM equipment uses the YASKAWA Electronics Series, the latest development of the group with increased control frequency and resolution of the encoder.

Improving these parameters has a positive effect on the speed and accuracy of the machine.

26.Step engines and controllers. THE BCAM machines are a step-by-step set of Leadshine controllers and Drivers. The devices are supplied directly from manufacturers, which 100% excludes the possibility of counterfeiting them.

At the moment, BCAM step drives with a capacity of 400 W are installed on large machines, and 200 watt on table milling

machines. The drives are characterized by high torque, providing the machines with dynamism and the ability to operate smoothly at accelerations of 1,500 m/s and above.

The accuracy of the step drive positioning is 3000 micro-steps per turn of the

shaft. In combination with the gearbox, the transmission number of which is 1:5, we get a hardware resolution of positioning of the machine equal to 0.006 mm. With this hardware resolution, contrary to popular misconception, the step of the drive does not affect the quality of work.

27.CNC SYSTEMS

We complete our CNC Router Machine with two systems depending on the purpose of the equipment:

Taiwan SYNTEC system is a simple, reliable and functional system, easily configurable for new hardware development and designed to replace the currently common remote systems to improve user performance for the operator and improve hardware performance.

Capabilities:

● Managing five a downs;

● Automatic change of tool taking into account the compensation of the lengths of the instruments at 3, 4 and 5 coordinate processing of the material.

● Accurate contouring of sheet materials with printed image using the German optical positioning system

● Manage two independent spindles on the axis of the axis, alternately performing milling various tools or working in copy mode;

● Control of the axis of rotation in 4D product processing;

● Manage the machine's various peripherals.

control panel:

At the disposal of the machine operator 19" touch display ka which displayed all parameters on the control of the machine.

With the operator panel, you can quickly set the processing speeds of the material on all aus, assign accelerations, set the safe height of the tool, the necessary processing accuracy, adjust the manual (fast and slow) and step-by-step movement, as well as a fixed distance of movement.

During the process of material processing, you can control and adjust the speed of movement of the tool and spindle revs in the range of 0 to 200%.

You can run and stop a management program from any line and store those parameters in the system's memory to resume. It is possible to start a management program in a step-by-step process while debugging a complex processing process or setting up a serial production.

The system can store an extensive list of control programs for the manufacture of serial products and gives the operator easy access to them and operational launch of execution.

The start of processing products can be made from one of the many base points that the operator can store in the memory of the system and use as the beginning of coordinates for one of the serial operations.

MPG Controller

For the convenience of the operator, in addition to the large touch display on the control desk, there is a manual remote control that controls the basic X Y Z 4axis Move and Setting parameters

Data interface

The device's memory is hosted through a local network or a USB interface. The programming language is G code.

Thanks to the network connection when contacting the service service of the company, CNC diagnostics can be made remotely, thus saving time for troubleshooting by the field engineer and related overheads.

28.German vision system

Designed to accurately cut through the contours of images printed on sheet materials.

Why you need a system ?

When printing images on sheet materials, it is possible to obtain images with deviations from the specified sizes, which presents some difficulties in further contouring on the frezer or laser equipment.

There are several reasons for the deviation of the image from the original size:

● Temperature deformation of sealed materials due to temperature differences in the rooms where the seal is made and cut on the contour. Even a slight change in temperature of 5-8 degrees can lead to a change in the size of a sheet of PVC by several millimeters. When you open, this deformation is manifested in the discrepancy between the printed image and the cutting path set by the original file.

● Technological features of printing on a UV printer with a lamp drying method, which leads to the heating of the material during printing. Once the printing is complete, the material cools down, exposing the temperature deformation and the printed image.

● Inconsistency in the setting of printing and cutting equipment, expressed in the small scale of the product in a larger or smaller way.

● The natural shrinkage of some materials after printing due to interaction with paint.

How it works, German Vision system:

The German Vision system, having obtained the original file on which the printing is made, scans optical tags at the edges of the image. Further contour cutting is made taking into account possible deformations of the imprint.

Compensation:

● The length and width of the image;

● The skew of diagonals;

● Trapezoidal deformity;

● The error when stacking an image on the desktop is relative to the beginning of the coordinates or with a turn.

Compensation is made instantly and automatically, without the involvement of an operator or any software product to correct the contouring file. At the same time, the indentation of the cut line from the edge of the image is saved.

There are no indentations or fields to place optical tags on the material. When preparing a printed file, the labels are placed close to the main image.

Benefits of using the system:

● The use of the German Vision improves the performance of both the printing of images and their further disclosure. When finding an optical mark, the system scans the field of 100x100 mm, almost independently finding an imprint on the desktop. Therefore, both in printing and contouring, there is no need to precisely base the processed material on the machine, thus saving part of the working time.

● In a replicated production, you can use a barcode at the bottom left optical tag to match the printed image with the selected cutting file. The system, believing it to independently choose the right file for cutting, will make it measured and cut.

Control of two spindles

In the two-spindle version of the axis machine, the axis is made as two independent systems with individual compensation for the departure of the instrument. This makes it much easier to set up when the material is consistently processed by different tools or the same work at the same time. The second spindle is used as a copyer when two tools work simultaneously. The machine in this case produces two products at a time.

The material sequential processing function is mainly designed for aluminum composite panel facade cassettes, which require a quick and frequent change of two instruments, occurring in 5 seconds.

The two-spinable version of the machine can also be used for simple operations, activating the work of the first or second spindle with the tools installed in them.

Automatic tool change

Automatic change of the instrument is made by the system in the classic 3 coordinate scheme of the equipment, as well as when using the rotation axis in 4D processing. The departure of each instrument from the cartridge is fixed by the system during the certification procedure and taken into account in processing. You can measure the level of the material being processed by any tool, regardless of the order of its use. To assess the departures of tools and to measure the surface level of the material, the machines are equipped with a remote sensor.

The amount of replacement tools supported is due only to the design of the machine. The toolbox can be located on the side and end of the machine, as well as on the portal or carriage during the revolver performance.

CNC RICHAUTO A11 ( A PLUS , S SERIES )

The RICHAUTO A11 control system is equipped with machines designed to solve simple three-axis engraving tasks and will be unveiled. It is a very common and reliable management system with a number of advantages, including:

● Convenience and ease of operation

● Mastering by the operator within a few hours

● highest resilience.

The button panel of the remote allows you to accurately position the tool over the material, choose and run tasks on milling, set and adjust during the work of milling parameters. Processing jobs are transferred via the USB interface. The programming language is G code.

CONCLUSION

CNC Router Machine is a collection of many systems responsible for the correctness of its operation. Since there are no superfluous components in the machine, even a short-term failure of one of them or an error in the operation of any system can lead to its complete shutdown. If you buy a machine with errors in design, then in the future will have to spend a lot of time and money, endlessly turning to the service service of the supplier in order to eliminate the again and again manifesting shortcomings.

BCAM produces really reliable equipment, requiring minimal warranty and post-guarantee service – Now in the world we have successfully operates about 2000 CNC Router Machine of our production, which serve only 6 service engineers, engaged mainly on start-ups of new equipment.

Many of our customers buy a second and a third as necessary to expand their production capabilities. Information about regular customers is presented in the "BCAM Equipment Working in the world" section on the main page of the site.

It is impossible to produce a quality machine, having installed on it the main set of quality elements and without paying similar attention to less significant components or simply without bothering to verify their authenticity and quality of performance. In the market now you can buy not only a quality counterfeit branded components, but also counterfeiting - in both cases, there is no need to talk about quality. Moreover, sooner or later the inevitable failure of the substandard structural element will lead to the shutdown of the machine.

In addition to quality control, we are attentive to the wishes of our customers and recommendations of service engineers, follow the development of other manufacturers of milling equipment, study information on profile forums. All positive experience is transferred to the design department, the work of which involves, among other things, the introduction of the necessary improvements to the model projects for the individual production tasks of the client or for the purpose of modernization.

This full description of the components we use may raise doubts among incredulous buyers about the authenticity of the above information. Call us during business hours - we will provide you with exhaustive technical advice on any issues you are interested in. In addition, we will provide documents confirming compliance with equipment and components to existing quality and safety standards at the first request. We also invite those wishing to visit our warehouse house and Demo place in CHINA,Dubai, UK,German,French,Italy ,USA,Korea,etc and personally test the equipment models you are interested in.

We value each of our clients and are always ready to meet your Demand!

- Previous : Making furniture By CNC wood router

- Next : Aggregate Head Aplication for Solid wood Funiture

EN

EN Ru

Ru