- Your are here:

- NEWS

Cabinets Production Process

Upload to:04-13 2022

Upload to:04-13 2022

The production process of panel furniture consists of many links and steps from the preparation of raw materials, through woodworking, paint finishing, and final product packaging and storage.

Panel furniture also has different technological processes due to different surface materials and surface decoration effects. The main representative categories are: veneer panel furniture, sticker panel furniture, solid color panel furniture, melamine panel furniture, and solid wood imposition furniture and Mixed category panel furniture consisting of one, two or more of the above categories.

Its main technological process includes material cutting, wood-based panel veneer, edge sealing, slot processing, packaging and assembly.

The complexity of the panel process is closely related to many factors such as the product's appearance design, product structure, materials, and the number of product varieties on the production line. For the drawer bottom plate, it only needs to be cut, and for the honeycomb hollow floor cabinet panel, it is The processing of a single panel requires more than 20 processes to complete.

The main components of the panel production process:

Raw materials, process documents, machinery and equipment, operators and corresponding quality and production management systems. Among them, the timely arrival of raw materials is the premise and foundation of the entire process, and the process documents are the action basis for the entire processing process and management activities. The process documents should be comprehensive and detailed.

Panel furniture process documents generally include: renderings, three views, parts exploded diagram, parts processing diagram, hardware accessories list, packaging scheme, installation schematic diagram, raw material list (BOM), parts processing process flow chart, product instruction manual .

Among them, the parts processing diagram should be used in conjunction with the parts processing process flow chart and run synchronously with the parts products on the production line to achieve the best effect.

The main contents in the parts processing flow table should cover the basic contents such as name, specification, quantity, material, batch, processing precautions, special inspection standard, working hours, process and serial number. Machines and equipment and operators are processing guarantees.

The main production process of panel furniture: Panel furniture also has different processes due to different surface materials and surface decoration effects. The main representative categories are: veneer panel furniture, sticker panel furniture, solid color panel furniture, melamine panel furniture And mixed category panel furniture consisting of one or more of the above categories.

Next, we use a table to understand the specific production process of panel furniture.

The production of panel furniture does not only require three steps of cutting, edge sealing and drilling, as most people think .

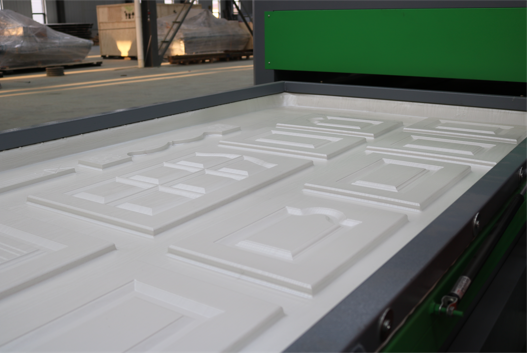

1. Cutting&Routing

Cutting is the process of cutting the panels used to make furniture. Due to the relatively simple structure of the panel furniture and the high precision of the connecting parts, the panel can be directly cut to the size of the required parts with a high-precision cutting saw during the cutting process.

The equipment used for cutting is mainly cutting saw. The commonly used cutting equipment in the production of traditional panel furniture is the precision panel saw, which is also often referred to as a "push table saw" because of its side with a pushable table.

The push table saw requires manual or semi-manual operation by workers. Each time a sheet is processed, the work intensity is relatively high, the work efficiency is relatively low, and the processing accuracy and safety factor are relatively low.

Another commonly used horizontal precision panel saw can be used for cutting multiple and large panels . It has large output and high precision, and is often used in large-scale production.

There are two types of advanced cutting equipment:

①Electronic cutting saw, also known as "computer panel saw", is an advanced digital processing equipment that can be used for cutting a variety of plates.

② CNC machining center cutting equipment, CNC machining center can be used for cutting the edge of the plate, the basic principle is to use a milling cutter to directly mill a groove with a depth exceeding the thickness of the plate along the edge of the plate, so as to achieve the purpose of cutting.

Among them, the most common application is the electronic cutting saw. The electronic cutting saw is widely used for processing various plywood, fiberboard, particleboard, ASS board, PVC board, plexiglass board and solid wood board and other structures, and cutting boards with similar hardness.

Features of electronic sizing saw:

①High cutting precision and low loss: the saw blade runs on the linear guide rail, avoiding the deviation of speed, strength, direction and other aspects caused by manual pushing, and the saw edge is accurate and neat.

②Safety and environmental protection: Infrared scanning, if there are foreign objects within 10cm of the saw blade , the saw blade will automatically sink to prevent accidents; the key-type dust-proof curtain can make the working environment cleaner and the sawing precision is higher. The entire cutting workshop is dusty, reducing the harm to people, the production environment is cleaner, and the noise is low.

③High efficiency: The number of jobs of one electronic cutting saw is equivalent to three push table saws . With the automatic lifting and feeding mechanism, fast feeding can be achieved.

④High accuracy: The telescopic ruler makes the long plate more accurate and saves the working space.

⑤The structure of the body is stable and firm: the body is welded with 150×75×5 square tubes and 20mm table tops, and then undergoes zero boundary temperature annealing treatment by large heat treatment equipment, which effectively removes the body stress and ensures the long-term sawing of the machine. Precision, but also to ensure that the body will never be deformed and durable.

⑥Simple operation: Since the data such as size is controlled by computer, there is less manual participation, so the level of workers is relatively low. Ordinary workers do not need to know much about furniture structure, etc., and can take up jobs after short-term training.

2. Wood-based panel veneer

Wood-based panel veneer includes a six-step process from cutting to trimming, which is the front-end process of panel furniture production. The wood-based panels purchased by the furniture factory are all substrates without decorative surface treatment.

Manufacturers should veneer the artificial surface according to the requirements of furniture design. There are many kinds of materials used for veneer, the common ones are melamine impregnated paper, thin veneer, decorative paper and so on.

The size deviation of the artificial board after cutting is large, and the veneer at this time will cause defects such as hollowing on the surface, which cannot be used. Therefore, it is necessary to sand the thickness of the plate before the veneer to make the surface as smooth as possible.

The equipment used for fixed thickness sanding is a broadband sander. The high-precision broadband sander can correct the size of the wood-based panel, make the thickness more uniform, and at the same time make the surface smoother, in preparation for subsequent surface decoration.

After sanding is completed, the substrate needs to be cleaned to remove surface impurities. The processed boards are veneered by the veneer assembly line. The veneer line is composed of a veneer, a hot press, a cooler, etc., which can semi-automatically complete the processes of gluing, veneer, hot pressing, quality inspection, cooling, and trimming with manual participation.

3. Edge sealing

Edge sealing is to use wood strips, thin strips, veneer strips, thin wood strips, melamine resin decorative strips, plastic film PVC strips, ABS strips, pre-painted decorative paper strips and other strip edge sealing materials. The edge of the panel is closed around the periphery of the panel. The substrate can be particleboard, medium density fiberboard, blockboard, double clad paneling, and the like.

The edge sealing of wood-based panels is an important part of the two processing of wood-based panels. By sealing the edges, the appearance quality of the furniture can be well improved, and the edges and corners of the furniture can be prevented from being damaged and the veneer layer being lifted or peeled off during transportation and use. At the same time, it can play the role of waterproofing, sealing the release of harmful gases and reducing deformation and cracking, and can also beautify furniture and pleasant mood.

There are many types of edge banding materials, and PVC edge banding strips are commonly used in custom furniture cabinets. A common method is to glue the edge strips to the sides of the panel with glue.

If the side of the board has a linear structure, it is called a straight edge; if the side of the board is a special-shaped structure, it is called a special-shaped edge. If the shape of the panel has a milled shape, post-forming edge sealing is required.

Straight edge sealing is relatively simple and efficient. Due to the influence of the special shape of the plate, the special-shaped edge sealing requires a high degree of manual participation and is relatively slow.

The tools used in the edge banding process are edge banding machines, including straight edge banding machines and special-shaped edge banding machines.

4. Slot hole processing (Boring ,Drilling ,Hinge )

钻孔样品照片

(1) Drilling

Various connector holes and round rod tenon holes need to be processed on furniture components. There are four main types:

①Connector hole: used to install and connect various connectors;

②Round tenon hole: used to install round rod tenon and locate parts;

③Hinge hole: used for the installation of various door hinges;

④Guide hole: used for the positioning of various screws and easy to screw in the self-tapping screw.

(2) Slotting

The slotting process can process various slots such as through slots, broken slots, and wire holes on various workpieces. The notches on panel furniture are generally used to install panels, such as the back of the cabinet, the bottom of the drawer, etc.; or to install various hardware accessories, such as sliding doors and other structural tracks, various cables, decorative strips Wait.

(开槽样品)

5. Packaging

Panel furniture is mostly flat-packed. The furniture when transported is disassembled and packed into smaller pieces. When it arrives at the customer's home, it is assembled on site . This not only fully saves the transportation space, but also reduces the transportation cost. The packaging of this kind of furniture is flat packaging.

(包装样品)

6. Assembly

The assembly of panel furniture is generally carried out at the seller or at the customer's home. The structure of panel furniture is relatively standardized, and the installation is relatively simple. The installer can install it correctly according to the factory-equipped installation

drawings. After the installation is complete, after checking it is correct, it can be delivered to the customer

(组装样品)

- Previous : Analysis and Solution of the Broken Knife of Woodworking cnc router machine

- Next : How to maintain your CNC wood cutting machine?

EN

EN Ru

Ru