- Your are here:

- NEWS

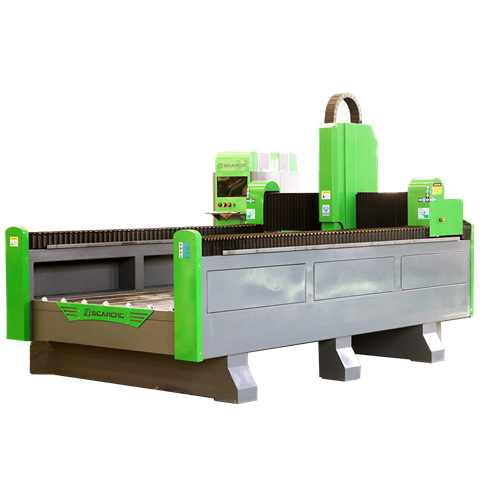

Some knowledge about stone cnc router machine configuration

Upload to:08-20 2021

Upload to:08-20 2021

Many customers buy stone cnc routers, and often hear the manufacturers talk about the configuration of the cnc routers. It is often the case that the manufacturers say a lot, and the customers do not know what it means. Next, the editor of BCAM will give you some knowledge about the configuration of the stone cnc router and make some suggestions.

The so-called cnc router configuration refers to the model, specification, brand, quantity, etc. of the components of the machine. Next, we make detailed explanations and suggestions:

1. First of all, we must determine the overall dimensions and engraving dimensions of the machine, including length, width, and height. If it is a multi-head cnc router, we must also focus on understanding the engraving size of each head when working with multiple heads and the size of engraving when working with single heads.

2. The bottom frame of the machine, also commonly known as "shelf", mainly refers to the size, specification and classification of the bottom frame. Just like when we invite people to eat, the table is full of food and cutlery, and the bottom shelf is like a table. It is the platform of the entire machine.

3. Cross beam, supporting and fixing the moving parts of X axis and Z axis.

4. The machine head, the cnc router performs processing and positioning through the movement of the machine head.

5. Precision machining on machine tools refers to the places where precision machining is required on the machine tools. Those CNC machine tools are used for machining. For example, lathes, milling machines, drilling machines, planers, double-arm planers, machining centers, etc. High-end machines are recommended to use machining centers for processing.

6. Heat treatment, machine tool chassis, gantry, machine head components, etc., if not treated after welding, the machine tool will deform over time. The longer the time, the greater the deformation. The heat treatment process is to eliminate and reduce this deformation.

7. The water tank, the machine uses circulating water to spray water on the cutter, and the water tank is where the water is stored. Mainly explain the material of the sink.

8. Countertop, it is the place where the stone work piece is put on the machine. There are many designs for countertops. Common ones include aluminum profile panels with soft PVC, aluminum profile strips inlaid with super-hard polyester panels, channel steel countertops with fixed super-hard polyester panels, and hollow countertops with fixed super-hard polyester panels. Channel steel countertops and hollowed-out countertops are convenient for machine tool cleaning, and are currently better countertop design methods.

9. Common materials for countertops are soft PVC and super-hard polyester plates. Soft PVC is easily damaged and affects the processing flatness. It is recommended to use super-hard polyester board.

10. The control card, which is the brain of the entire stone cnc router, reads and analyzes programming files and outputs processing signals. All movement on the machine tool originates from the signal output by the control card.

11. The spindle is also called "spindle motor" and "electric spindle", because machining requires tool rotation, and the spindle drives the tool to rotate through its own rotation. The main shaft is the main vulnerable part of the stone cnc router, and it is difficult for non-professionals to repair it locally, so it usually needs to be returned to the factory for repair. It is recommended to use a well-known brand spindle motor with a power of not less than 5.5 kilowatts (including 5.5 kilowatts). Especially for customers who engrave reliefs and granite stone, please do not use low-power spindles.

12. The frequency converter receives the rotation signal sent by the computer, outputs a variable current, and drives the main shaft to work. Recommend two domestic inverter brands that are easy to use, "Sifang Inverter" and "Delta Inverter".

13. Working voltage, the voltage at which the machine is connected to the power supply, mainly uses 380 volts three-phase electricity and 220 volts single-phase electricity.

14. The drive motor is responsible for the power output of the cnc router in all directions. There are four common types: stepper motors, hybrid servo motors, domestic servo motors, and imported servo motors. To drive the motor, I recommend that customers do what they can and don’t blindly. The motor chooses a motor with a better working principle but a poor quality, and it often fails frequently, causing considerable trouble to the user.

15. The driver, matched with the drive motor, outputs current and motion signals for the drive motor.

16. Guide rails and sliders guide the direction of movement of each part of the machine, and use rolling movement to reduce movement resistance. The use of guide rails on the cnc router mainly includes circular rails and square rails. The first-line brands are genuine square rails imported from Taiwan's Shanghai Yintai and Yintai, the second-line are genuine square rails imported from Taiwan TBI, CSK, and the third-line are domestic square rails, including imitation rails and self-designed rails. As we all know, Taiwan's machining and processing technology is very advanced. I am not completely denying the domestic guide rails. It is just that there are many types of domestic guide rails on the market, and fakes are rampant. In contrast, Taiwan guide rails are more secure.

17. Rack, the gear of the drive motor meshes with the rack, the motor rotates, and the gear and rack move relative to each other. Common teeth include straight teeth, helical teeth, and herringbone teeth.

18. Lead screw, lead screw drive and rack drive are all common transmission methods of cnc routers. The lead screw rotates to drive the movement of machine parts. Most of the heavy-duty stone cnc routers are rack machines, the X axis (left and right direction) and Y axis (front and back direction) are rack drive, and the Z axis (up and down direction) is screw drive. The reason why the lead screw is more important is that the quality of the lead screw affects the accuracy of the Z movement in the up and down direction, and the second is that once the lead screw is damaged, it is troublesome to disassemble and assemble. Recommend Taiwan Yintai and Taiwan TBI brands.

19. Cables are used to connect the various circuit components of the machine. The cable is mainly the cable of the drive motor and the cable of the spindle motor. It is recommended to use towline cables of well-known brands.

20. Reducer, gear boxes and reducers are common on cnc routers. The reducer has high precision and stable operation, but it is expensive. At present, more than 95% of domestic cnc routers use gear box deceleration. If assembled, they are relatively durable, with low cost and good performance-to-price ratio. Customers are expected to do what they can. No matter what kind of product they buy, choosing a good type but poor quality accessory is far less reliable than choosing an economically stable one.

21. The Z-axis fastening method refers to the connection and fastening method between the Z-axis drive motor shaft and the upper end of the screw. Commonly used are belt pulley fastening and coupling direct connection fastening.

22. The power distribution cabinet is the place where the main electrical components of the stone cnc router are assembled. Commonly there are independent cabinets and computer cabinets.

23. Pulley, when the cnc router feeds, the stone can be pushed on the pulley to reduce resistance.

24. The switch, a circuit component, controls the on and off of the current through "open" and "close".

The above are some configuration equipment and small knowledge of the machine, we will update the knowledge about the cnc router regularly, please continue to pay attention to us: https://www.bcamcnc.com/

- Previous : What is the difference between the water-cooled and air-cooled spindles of the cnc router

- Next : How to control the frequency conversion of the aluminum cnc router

EN

EN Ru

Ru