- Your are here:

- Home >

- Kronospan Cabinets Case Studies

Kronospan Cabinets Case Studies

Upload to:12-26 2022

Upload to:12-26 2022

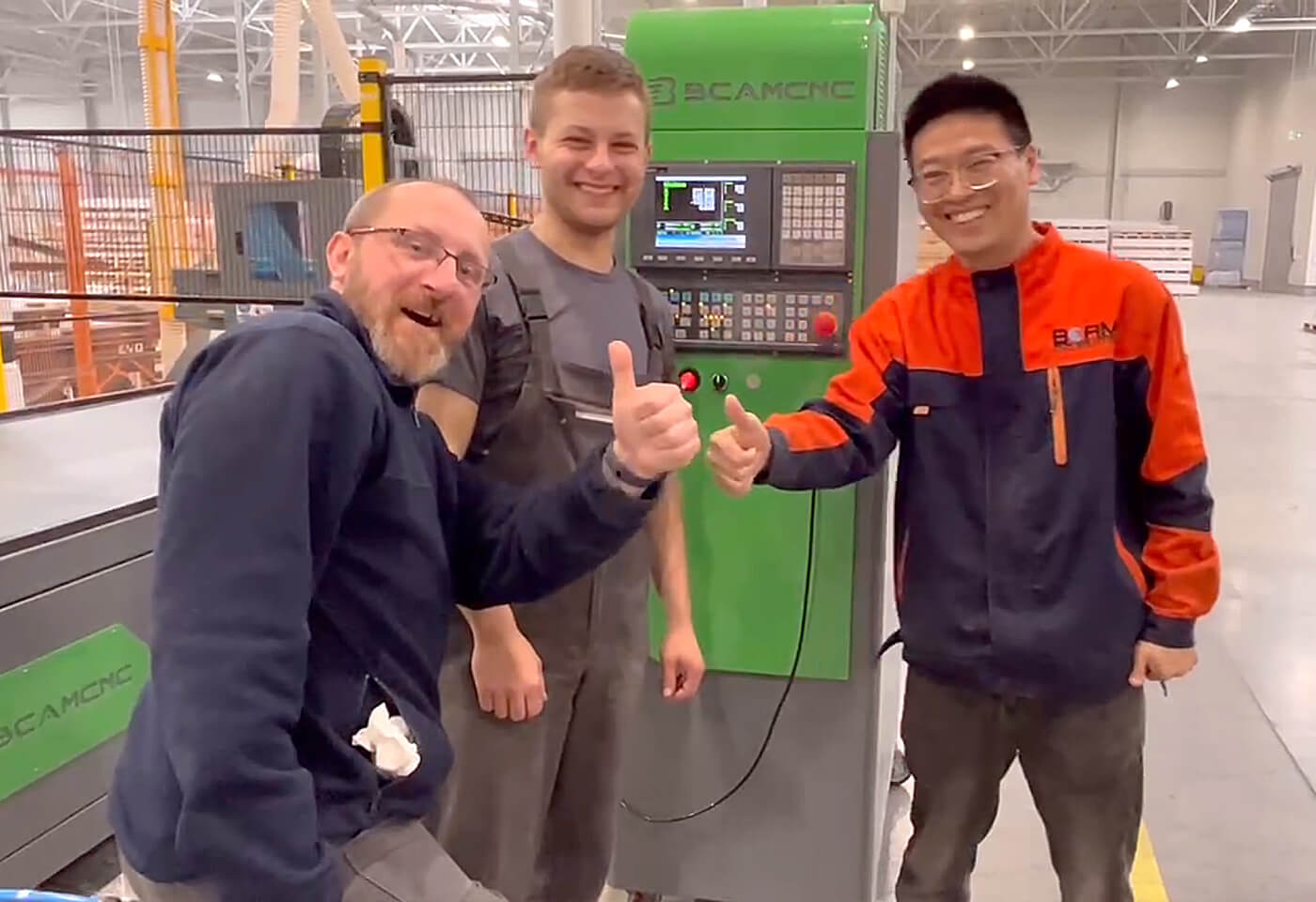

Kronospan needs a CNC Router with a working area of 1300*2800 mm and a production speed of 700 boards per day. This machine is mainly used for cutting SPC sheet and other materials.Kronospan took a fancy to a CNC Router from BCAMCNC.

After a month-long communication and negotiation, he placed an order with our company and started a long-term cooperative relationship.CNC Router is a high-precision automated equipment that can precisely cut plates according to pre-designed drawings and programs.BCAMCNC's CNC Router is very suitable for Kronospan's daily work requirements, which will bring many advantages to Kronospan's production process.

BCMANCN's CNC Router can process larger-sized plates at the same time due to its large working area, which improves production efficiency.

The production speed of 700 panels per day can meet the company's production needs and ensure the stability of product supply.

BCMANCN's CNC Router In terms of cutting SPC plates, BCAMCNC's CNC Router can achieve high-precision and smooth cutting process, ensure the consistency of plate size, and improve product quality. For the cutting of other materials, it only needs to adjust the program according to the characteristics of different materials to achieve precise cutting requirements.Bcamcnc is a professional machinery manufacturing company with a production factory of 6000 square meters, well-equipped and superior production environment.

The company has a highly specialized and experienced workforce, covering expertise in many fields. At the same time, the company also has more than 10 patented technologies, the research and development and application of these technologies make Bcamcnc famous in the industry.As a leading manufacturer dedicated to CNC technology, Bcamcnc has built a good reputation worldwide.

The company is famous for its excellent technical strength and high-quality products, and has become the preferred partner of many customers. Whether in innovative design, precision manufacturing or after-sales service, Bcamcnc always adheres to the principles of professionalism, reliability and efficiency, and provides customers with comprehensive and satisfactory solutions.In short, with its strong technical strength, professional manufacturing level and reliable product quality,

Bcamcnc has won the trust and recognition of customers all over the world, and has become one of the highly respected and well-known enterprises in the CNC field.

We will continue to complete the communication in 2023 and expect to purchase our woodworking production line equipment in December.Cut sheet (size 6x2.2m)During the production process, this equipment can efficiently carry out precise cutting of large-size plates. Whether it is long or wide, it can meet the plate size requirements of 6x2.2 meters, providing more possibilities for furniture manufacturing.

Edge strips (PVC, ABS, paper - from the thinnest on the market to 2 mm), drilled, stacked, packed into pallets.This set of equipment can not only add sidebands of various materials to the board, such as PVC, ABS, paper, etc., but also perform precise drilling operations. Moreover, the intelligent stacking and pallet packing functions of the equipment can ensure the neat stacking and convenient transportation of parts and components.

The processing volume is 10,000 cubic meters (60,000 square meters) per 24 hours.The high capacity of the plant is impressive, with a capacity of processing 10,000 cubic meters of material per day, equivalent to 60,000 square meters of sheet metal. This will greatly improve production efficiency and meet high production demands.The thickness of the sheet can be 8-40mm.Whether it is a thinner 8mm plate or a thicker 40mm plate, this set of equipment can easily handle it and meet the processing requirements of plates of different thicknesses.A post-cut buffer was also required to accommodate 24-hour production in 10 different formats.

The equipment can not only cut efficiently, but also take into account the continuity of production. In order to cope with the production of different formats, the equipment provides a buffer zone after cutting to ensure a smooth production process.Production control and automation systems (to minimize manual operations)The equipment is equipped with advanced production control and automation system, which greatly reduces the need for manual operation. This will increase productivity and reduce the risk of human error.

Optional - laser sideband processing

As an additional option, the equipment also provides the laser sideband processing function to further improve the accuracy and efficiency of sideband processing.

Optional - Protective film after cutting.

For applications that need to protect the surface of the board, the equipment also provides an optional protective film function after cutting to ensure product quality and appearance.

This set of fully automatic furniture parts production equipment not only has excellent technical capabilities, but also provides flexible options in different aspects to meet the diverse needs of the furniture manufacturing industry.

EN

EN Ru

Ru