- Your are here:

- Woodworking CNC router machine tools introduction

Woodworking CNC router machine tools introduction

Upload to:12-10 2018

Upload to:12-10 2018

Computer digital control technology can open up new creativity and possibilities, which is particularly prominent in the field of woodworking CNC. But the best CNC router machine needs to be matched with the right tool, so that the two can complement each other.

Tools for CNC router machines usually have two grooves or cutting edges. In general, cutting tips that remove less debris will remove more material per cut and require a slower feed rate, while drills with more grooves will leave a smoother cutting surface. And faster feed speeds are needed to avoid burning.

Let's take a look at some of the most widely used CNC router tools and what can they do?

V-knife

As the name implies, these drill bits have a "V" shaped cutting profile. However, they can have different "angles", which also determines their different uses.

A 90° drill cuts a wider path, so it is more suitable for cutting larger or lighter letters or details; while a 60° drill has a tighter angle, allowing for smaller text and detail, or deeper engraving Cutting, sharper contrasting shadows, etc.

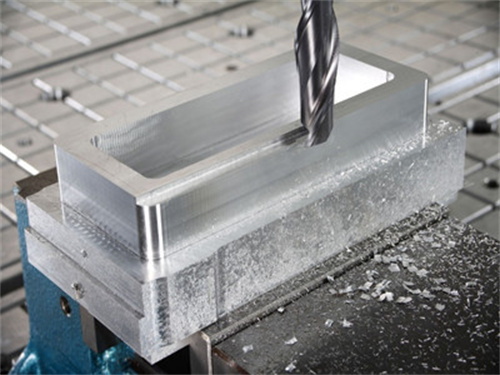

End mill bit

These drills cut straight, but spiral flutes, leaving a flat bottom when cleaning the chips and grooves. They can be used for digging, grooving and drilling, so they are very versatile.

A 1/4" diameter spiral cutting bit is a good starting point, but please note that in general, CNC router machines do not use standard straight cutting heads.

Ball milling

If you want to do embossing, ball milling is necessary. Commonly used sizes are 1/4", 1/8" and 1/16". If you use them to remove material from a larger area, they will leave a small ridge that cuts over and overlaps, creating a fan-shaped visual effect. Ridges are undesirable and can be eliminated by reducing the step size of the tool path.

In addition, ball-end milling can also be used for grooved woodwork, signage and decorative texture engraving for plywood, cork and hardwood cutting.

Tapered ball milling

With tapered ball-end milling, you can enjoy fast and fine cuts on a variety of 2D and 3D engravings. The drill bit is ideal for cutting wood, wood composites, hard and soft plastics as well as aluminum.

The conical ball head can be highly precise, and the spiral groove helps pull dust and debris up the cut to prevent clogging. The solid carbide structure provides excellent strength properties and a long-lasting cutting edge.

Surfacing drill

If you want to re-lay the disc on a CNC router machine, this larger cutter will be more precise and work shorter. It can quickly smooth any high or low point and produce a nice flat reference surface.

Replaceable carbide inserts mean longer life and less grinding time.

EN

EN Ru

Ru